EQUAL TEE ANSI B 16.9

Forged Equal Tees, Equal Tees Socket Weld, Equal Tees Threaded, Seamless Equal Tees, Welded Equal Tees

Stainless Steel Tee, Carbon Steel Tee, Alloy Steel Tee and Nickel Based High Alloy Tee

Manufacturer and Exporter's of Equal Tee ANSI B 16.9 in India

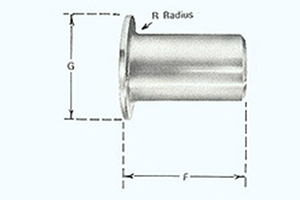

Stub Ends are fittings used in place of welded flanges where rotating back up flanges are desired. They are also called Lap Joints and Vanstone Flared Laps. A rotating back up flange seats itself against the back surface of the Stub End. When bolts are added, the clamping action of the bolts presses the rotating back up flange against the back of the Stub End. The gasket surface of the Stub End then presses against a gasket and another gasket surface providing joints like standard flange joints. The seal is made by the gasket surface of the stub end alone, the flange only provides the clamping pressure on the joint. Our high quality stub ends (Butt weld fittings) are tested and verified for durability, accuracy and precision. The stub ends are manufactured in all standard dimensions. The stub ends are provided with a standard weld bevel and can be available in squared, flanged, victaulic and threaded ends. We offer stub ends at highly competitive prices.

Stub Ends are fittings used in place of welded flanges where rotating back up flanges are desired. They are also called Lap Joints and Vanstone Flared Laps. A rotating back up flange seats itself against the back surface of the Stub End. When bolts are added, the clamping action of the bolts presses the rotating back up flange against the back of the Stub End. The gasket surface of the Stub End then presses against a gasket and another gasket surface providing joints like standard flange joints. The seal is made by the gasket surface of the stub end alone, the flange only provides the clamping pressure on the joint. Our high quality stub ends (Butt weld fittings) are tested and verified for durability, accuracy and precision. The stub ends are manufactured in all standard dimensions. The stub ends are provided with a standard weld bevel and can be available in squared, flanged, victaulic and threaded ends. We offer stub ends at highly competitive prices.

Prosaic Steel & Alloys manufactures a wide range of stub ends (pipefitting) made of materials - exotic metals, nickel, cupro-nickel, Stainless Steel etc., of various grades. Prosaic Steel & Alloys manufactures & supplies high quality stub ends (pipe fittings) that can be used for various applications. Our stub ends are tested and verified for durability, accuracy and precision.

Prosaic Steel & Alloys manufactures seamless stub ends of long & short radius to MSS and ANSI B 16.9 standard from Schedules 10 to 160.

Prosaic Steel & Alloys designs & manufactures subtends (pipe fitting) of special type made according to drawing on request.

Material: A234-WPB A234-WP12 A234-WP11 A234-WP5 A403-WP304 A403-WP304L A403-WP316. A403-WP316L A420-WPL6, 316L, 304L, 321, 321H.

Size: 1/2" - 24"

Types: Type A, Type B, Type C, Type D

Manufacturing standard: ASME/ANSI B16.9, JIS, DIN, EN, API 5L, etc.

Surface treatment: Shot blasted, rust-proof black oil

| INCHES | METRIC | ||||||||||||

| N.B. | O.D. At Bevel | F | Rad. Of Fillet R | Dia of Lap G | O.D. Of Barrel | N.B. | O.D. At Bevel | F | Rad. Of Fillet R | Dia of Lap G | O.D. Of Barrel | ||

| Max. | Min. | Max. | Min. | ||||||||||

| 1 - 2 |

0.84 | 3 | 1 - 8 |

1-3/8 | 0.9 | 0.81 | 15 | 21.34 | 76.2 | 3.18 | 34.93 | 22.76 | 20.55 |

| 3 - 4 |

1.05 | 3 | 1 - 8 |

1 11/16 | 1.11 | 1.02 | 20 | 26.67 | 76.2 | 3.18 | 42.86 | 28.09 | 25.88 |

| 1 | 1.32 | 4 | 1 - 8 |

2 | 1.38 | 1.28 | 25 | 33.4 | 101.6 | 3.18 | 50.8 | 34.95 | 32.61 |

| 1-1/4 | 1.66 | 4 | 3 - 16 |

2-1/2 | 1.72 | 1.63 | 32 | 42.16 | 101.6 | 4.76 | 63.5 | 43.59 | 41.38 |

| 1 1/2 | 1.9 | 4 | 1 - 4 |

2 7/8 | 1.97 | 1.87 | 40 | 48.26 | 101.6 | 6.35 | 73.03 | 49.94 | 47.47 |

| 2 | 2.38 | 6 | 5 - 16 |

3 5/8 | 2.46 | 2.34 | 50 | 60.33 | 152.4 | 7.94 | 92.08 | 62.38 | 59.54 |

| 2-1/2 | 2.88 | 6 | 5 - 16 |

4 1/8 | 2.97 | 2.84 | 65 | 73.03 | 152.4 | 7.94 | 104.78 | 75.34 | 72.24 |

| 3 | 3.5 | 6 | 3 - 8 |

5 | 3.6 | 3.47 | 80 | 88.9 | 152.4 | 9.53 | 127 | 91.34 | 88.11 |

| 3 1/2 | 4 | 6 | 3 - 8 |

5 1/2 | 4.1 | 3.97 | 90 | 101.6 | 152.4 | 9.53 | 139.7 | 104.04 | 100.81 |

| 4 | 4.5 | 6 | 7 - 16 |

6 3/16 | 4.59 | 4.47 | 100 | 114.3 | 152.4 | 11.11 | 157.16 | 116.66 | 113.51 |

| 5 | 5.56 | 8 | 7 - 16 |

7 5/16 | 5.68 | 5.53 | 125 | 141.3 | 203.2 | 11.11 | 185.74 | 144.35 | 140.51 |

| 6 | 6.63 | 8 | 1 - 2 |

8 1/2 | 6.74 | 6.59 | 150 | 168.28 | 203.2 | 12.7 | 215.9 | 171.27 | 167.49 |

| 8 | 8.63 | 8 | 1 - 2 |

10 5/8 | 8.74 | 8.59 | 200 | 219.08 | 203.2 | 12.7 | 269.88 | 222.07 | 218.29 |

| 10 | 10.75 | 10 | 1 - 2 |

12 3/4 | 10.91 | 10.72 | 250 | 273.05 | 254 | 12.7 | 323.85 | 277.19 | 272.26 |

| 12 | 12.75 | 10 | 1 - 2 |

15 | 12.91 | 12.72 | 300 | 323.85 | 254 | 12.7 | 381 | 327.99 | 323.06 |

| 14 | 14 | 12 | 1 - 2 |

16 1/4 | 14.17 | 13.97 | 350 | 355.6 | 304.8 | 12.7 | 412.75 | 359.92 | 354.81 |

| 16 | 16 | 12 | 1 - 2 |

18 1/2 | 16.18 | 15.97 | 400 | 406.4 | 304.8 | 12.7 | 469.9 | 410.97 | 405.61 |

| 18 | 18 | 12 | 1 - 2 |

21 | 18.19 | 17.97 | 450 | 457.2 | 304.8 | 12.7 | 533.4 | 462.03 | 456.41 |

| 20 | 20 | 12 | 1 - 2 |

23 | 20.24 | 19.97 | 500 | 508 | 304.8 | 12.7 | 584.2 | 514.1 | 507.21 |

| 22 | 22 | 12 | 1 - 2 |

25 1/4 | 22.24 | 21.97 | 550 | 558.8 | 304.8 | 12.7 | 641.35 | 564.9 | 558.01 |

| 24 | 24 | 12 | 1 - 2 |

27 1/4 | 24.24 | 23.97 | 600 | 609.6 | 304.8 | 12.7 | 692.15 | 615.7 | 608.81 |