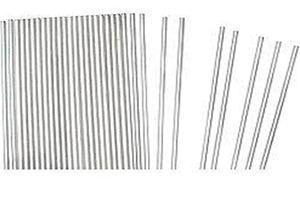

Stainless Steel Capillary Tubes (Precision Tubes)

Stainless Steel Capillary Tubes and Tubing | Seamless Capillary Tubes | Semi Welded Capillary Tubes in Straight and Coil Form

Stainless Steel Capillary Tubes in Grade 304, 304L, 304H, 309, 310s, 316, 316L, 316Ti, 317L, 321, 321H, 347, 347H, 904L etc

Manufacturer, Stockholder, Distributor, Exporter and Supplier of Stainless Steel Capillary Tubes and Tubing based in India. High Quality Stainless Steel Capillary Tubes and Tubing at Competitive Price. Stainless Steel Capillary Tubes and Tubing Ready Stock Inventory of more than 10000 Metric Ton. Stainless Steel Capillary Tubes and Tubing our Speciality

Capillary pipes and Capillary tubes in small bore sizes and precise thickness are available as per the requirements of clients. Exceedingly demanded in precise apparatus & instruments, automatic instruments, electronic parts, oil & gas plants and other industries.

Capillary pipes and Capillary tubes in small bore sizes and precise thickness are available as per the requirements of clients. Exceedingly demanded in precise apparatus & instruments, automatic instruments, electronic parts, oil & gas plants and other industries.

We are one of the reputed Capillary Pipes and Tubes Exporters and Suppliers in India. The Stainless Steel Capillary Tubes that we bring forth in the industry is accessible in varying lengths, Size and grades. Their sizes range from 0.30 mm to 8.00 mm. They can be availed in thin, standard or heavy wall. Stainless Steel Capillary Pipes & Tubes are used in different applications of intra/extra cellular biology, separation sciences, hematology sampling and study, biotechnology, and biochemistry.

Capillary Tube is a long, narrow tube of constant diameter. The word "capillary” is a misnomer since surface tension is not important in refrigeration application of capillary tubes.

Typical tube diameters of refrigerant capillary tubes range from 0.30 mm to 31.75 mm O.D. And 0.06 mm to 1.65 mm thickness and the length ranges from 1.0 mm to 6.0 mm. It & is widely used in instrumentation Industries.

Primary Application of Stainless Steel capillary tubes for medical needle.

| Stainless Steel capillary tubes for medical needle Grade | Straight/ Coil tubing TP 202, TP 304, TP 304L, TP 316/316L, TP321, TP316SS TP310S/ Incoloy800/825/600/625/718 Monel400/ K-50 etc. |

| Stainless Steelcapillary tubes for medical needle Standard | Straight/ Coil tubing ASTM, GB, AISI, JIS, DIN,EU |

| Stainless Steelcapillary tubes for medical needle Diameter | Straight/ Coil tubing 0.33mm-76mm |

| Stainless Steelcapillary tubes for medical needle Thickness | Straight/ Coil tubing 0.1mm-3.0mm |

| Stainless Steelcapillary tubes for medical needle Length | Straight/ Coil tubing Depending on your requirement 50-2000meters |

| Stainless Steelcapillary tubes for medical needle Technique | Straight/ Coil tubing Cold drawing, precision rolling |

Stainless steels are also classified by their crystalline structure:

Austenitic, or 300 series, Stainless steels make up over 70% of total stainless steel production. They contain a maximum of 0.15% carbon, a minimum of 16% chromium and sufficient nickel and/or manganese to retain an austenitic structure at all temperatures from the cryogenic region to the melting point of the alloy. A typical composition of 18% chromium and 10% nickel, commonly known as 18/10 stainless, is often used in flatware. 18/0 and 18/8 are also available. Superaustenitic stainless steels, such as alloy AL-6XN and 254SMO, exhibit great resistance to chloride pitting and crevice corrosion due to high molybdenum content (>6%) and nitrogen additions, and the higher nickel content ensures better resistance to stress-corrosion cracking versus the 300 series. The higher alloy content of superaustenitic steels makes them more expensive. Other steels can offer similar performance at lower cost and are preferred in certain applications.[citation needed] Low-carbon versions, for example 316L or 304L, are used to avoid corrosion problems caused by welding. Grade 316LVM is preferred where biocompatibility is required (such as body implants and piercings).[15] The "L" means that the carbon content of the alloy is below 0.03%, which reduces the sensitization effect (precipitation of chromium carbides at grain boundaries) caused by the high temperatures involved in welding.

Ferritic stainless steels generally have better engineering properties than austenitic grades, but have reduced corrosion resistance, due to the lower chromium and nickel content. They are also usually less expensive. They contain between 10.5% and 27% chromium and very little nickel, if any, but some types can contain lead. Most compositions include molybdenum; some, aluminium or titanium. Common ferritic grades include 18Cr-2Mo, 26Cr-1Mo, 29Cr-4Mo, and 29Cr-4Mo-2Ni. These alloys can be degraded by the presence of σ chromium, an intermetallic phase which can precipitate upon welding.

Martensitic stainless steels are not as corrosion-resistant as the other two classes but are extremely strong and tough, as well as highly machinable, and can be hardened by heat treatment. Martensitic stainless steel contains chromium (12–14%), molybdenum (0.2–1%), nickel (less than 2%), and carbon (about 0.1–1%) (giving it more hardness but making the material a bit more brittle). It is quenched and magnetic.

Precipitation-hardening martensitic stainless steels have corrosion resistance comparable to austenitic varieties, but can be precipitation hardened to even higher strengths than the other martensitic grades. The most common, 17-4PH, uses about 17% chromium and 4% nickel. The Lockheed-Martin Joint Strike Fighter is the first aircraft to use a precipitation-hardenable stainless steel -Carpenter Custom 465—in its airframe.

Duplex stainless steels have a mixed microstructure of austenite and ferrite, the aim usually being to produce a 50/50 mix, although in commercial alloys the ratio may be 40/60. Duplex stainless steels have roughly twice the strength compared to austenitic stainless steels and also improved resistance to localized corrosion, particularly pitting, crevice corrosion and stress corrosion cracking. They are characterized by high chromium (19–32%) and molybdenum (up to 5%) and lower nickel contents than austenitic stainless steels. Duplex grades are characterized into groups based on their alloy content and corrosion resistance. Lean duplex refers to grades such as UNS S32101 (LDX 2101), S32304, and S32003. The standard duplex is 22% chromium with UNS S31803/S32205 known as 2205 being the most widely used. Super duplex is by definition a duplex stainless steel with a pitting corrosion equivalent (PRE) > 40, where PRE = %Cr + 3.3x(%Mo + 0.5x%W) + 16x%N. Usually super duplex grades have 25% chromium or more and some common examples are S32760 (Zeron 100), S32750 (2507) and S32550 (Ferralium), although not

all Ferralium grades are super duplex grades. Hyper duplex refers to duplex grades with a PRE > 48 and at the moment only UNS S32707 and S33207 are available on the market. The properties of duplex stainless steels are achieved with an overall lower alloy content than similar-performing super-austenitic grades, making their use cost-effective for many applications.

We Exports & Manufactures in Typical sizes of capillary pipes & Tubes

Capillary Pipes & Tubes are used in major below applications, such as:

- Stainless Steel Capillary Tubes in Chromatography

- Stainless Steel Capillary Tubes in Gas and liquid lines

- Measurement components in remote thermometer systems (with or without compensation)

- Stainless Steel Capillary Tubes in Medical needle

- Stainless Steel Capillary Tubes in Scientific research

- Stainless Steel Capillary Tubes in Chemical industry

- Stainless Steel Capillary Tubes in Thermal conductivity temperature control device

- Stainless Steel Capillary Tubes in Telecom device:miniature antenna tube

Why You Choose Us For Stainless Steel Capillary Tubes

We Prosaic Steel and Alloys have been the most trusted name in Stainless Steel Capillary Tubes industry for quite a long time. With our exported product from the international market, every sing being of the high quality have never put our customers hopes down. With the stocks of tubes on all grades we have been sincere enough in meeting all customer needs.

Since 1972, nearly 42 years of experiment and experience, we explored and summarized the way to control the optimum temperature at the process of manufacture, which guarantee our products are good-looking, smooth both inside and outside; decelerate the aging problem, and the roughness is controlled not more than 5um.

We export Stainless Steel Capillary Tubes everywhere in the world

We have our own warehouse, so we can offer Stainless Steel Capillary Pipes best price in the market.

Stainless Steel Capillary Tubes

- 304 Stainless Steel Capillary Tubes

- 304H Stainless Steel Capillary Tubes

- 304L Stainless Steel Capillary Tubes

- 309S Stainless Steel Capillary tubes

- 309H Stainless Steel Capillary tubes

- 310S Stainless Steel Capillary tubes

- 310H Stainless Steel Capillary tubes

- 316 Stainless Steel Capillary tubes

- 316H Stainless Steel Capillary Tubes

- 316TI Stainless Steel Capillary tubes

- 316L Stainless Steel Capillary Tubes

- 316LN Stainless Steel Capillary Tubes

- 317 Stainless Steel Capillary Tubes

- 317L Stainless Steel Capillary Tubes

- 321 Stainless Steel Capillary Tubes

- 321H Stainless Steel Capillary Tubes

- 347 Stainless Steel Capillary Tubes

- 347H Stainless Steel Capillary Tubes

- 904L Stainless Steel Capillary Tubes

Comparison of standardized Stainless Steels

| Outside Diameter in. (mm) | Inside Diameter in. (mm) | Mean Wall Thickness in. (mm) | Weight in/ft. (Kg/m) | Maximum Allowable Residue g/ft. g/m) |

| 0.072(1.83) | 0.026(0.660) | 0.023(0.584) | 0.01373(0.0204) | 0.00020(0.000656) |

| 0.072(1.83) | 0.028(0.711) | 0.022(0.558) | 0.01340(0.0199) | 0.00021(0.000689) |

| 0.081(2.06) | 0.031(0.787) | 0.025(0.635) | 0.01705(0.0254) | 0.00023(0.000754) |

| 0.081(2.06) | 0.033(0.838) | 0.024(0.606) | 0.01666(0.0248) | 0.00025(0.000820) |

| 0.087(2.21) | 0.036(0.914) | 0.0255(0.648) | 0.01910(0.0284) | 0.00027(0.000886) |

| 0.087(2.21) | 0.039(0.991) | 0.024(0.606) | 0.01842(0.0239) | 0.00029(0.000951) |

| 0.093(2.36) | 0.042(1.07) | 0.0255(0.648) | 0.02096(0.0312) | 0.00032(0.00105) |

| 0.097(2.47) | 0.046(1.17) | 0.025(0.648) | 0.02221(0.0331) | 0.00035(0.00115) |

| 0.099(2.51) | 0.049(1.24) | 0.025(0.635) | 0.02253(0.0335) | 0.00037(0.00121) |

| 0.106(2.69) | 0.054(1.37) | 0.026(0.660) | 0.02533(0.0377) | 0.00041(0.00134) |

| 0.112(2.84) | 0.059(1.50) | 0.0265(0.673) | 0.02760(0.0411) | 0.00044(0.00144) |

| 0.125(3.18) | 0.064(1.63) | 0.0305(0.775) | 0.03511(0.0522) | 0.00048(0.00157) |

| 0.125(3.18) | 0.070(1.78) | 0.0275(0.698) | 0.03266(0.0486) | 0.00053(0.00174) |

| 0.125(3.18) | 0.075(1.91) | 0.025(0.635) | 0.03054(0.0454) | 0.00057(0.00187) |

| 0.145(3.68) | 0.080(2.03) | 0.0325(0.826) | 0.04453(0.0663) | 0.00060(0.00197) |

| 0.145(3.68) | 0.085(2.16) | 0.030(0.762) | 0.04202(0.0625) | 0.00064(0.00210) |

| 0.145(3.68) | 0.090(2.29) | 0.0275(0.698) | 0.03936(0.0586) | 0.00068(0.00223) |

| 0.160(4.06) | 0.100(2.54) | 0.030(0.762) | 0.04750(0.0707) | 0.00075(0.00246) |

| 0.160(4.06) | 0.110(2.79) | 0.025(0.635) | 0.04111(0.0611) | 0.00083(0.00272) |

| 0.188(4.78) | 0.120(3.03) | 0.034(0.864) | 0.06377(0.0949) | 0.00090(0.00295) |

Stainless Steel Capillary Tubes, Seamless, Semi Welded, Welded and Tubes Available Ex-Stock:

304 Stainless Steel Capillary Tubes and Tubing – Available ex-Stock

304L Stainless Steel Capillary Tubes and Tubing – Available Ex-Stock

304H Stainless Steel Capillary Tubes and Tubing – Available Ex-Stock

309 Stainless Steel Capillary Tubes and Tubing – Available Ex-Stock

310 Stainless Steel Capillary Tubes and Tubing – Available Ex-Stock

310S Stainless Steel Capillary Tubes and Tubing – Available Ex-Stock

316 Stainless Steel Capillary Tubes and Tubing – Available Ex-Stock

316L Stainless Steel Capillary Tubes and Tubing – Available Ex-Stock

316Ti Stainless Steel Capillary Tubes and Tubing – Available Ex-Stock

321/321H Stainless Steel Capillary Tubes and Tubing – Available Ex-Stock

347/347H Stainless Steel Capillary Tubes and Tubing – Available Ex-Stock

304 Stainless Steel Capillary Tubes and Tubing – Available ex-Stock

304L Stainless Steel Capillary Tubes and Tubing – Available Ex-Stock

304H Stainless Steel Capillary Tubes and Tubing – Available Ex-Stock

309 Stainless Steel Capillary Tubes and Tubing – Available Ex-Stock

310 Stainless Steel Capillary Tubes and Tubing – Available Ex-Stock

310S Stainless Steel Capillary Tubes and Tubing – Available Ex-Stock

316 Stainless Steel Capillary Tubes and Tubing – Available Ex-Stock

316L Stainless Steel Capillary Tubes and Tubing – Available Ex-Stock

316Ti Stainless Steel Capillary Tubes and Tubing – Available Ex-Stock

321/321H Stainless Steel Capillary Tubes and Tubing – Available Ex-Stock

347/347H Stainless Steel Capillary Tubes and Tubing – Available Ex-Stock

304 Stainless Steel Capillary Tubes and Tubing – Available ex-Stock

304L Stainless Steel Capillary Tubes and Tubing – Available Ex-Stock

304H Stainless Steel Capillary Tubes and Tubing – Available Ex-Stock

309 Stainless Steel Capillary Tubes and Tubing – Available Ex-Stock

310 Stainless Steel Capillary Tubes and Tubing – Available Ex-Stock

310S Stainless Steel Capillary Tubes and Tubing – Available Ex-Stock

316 Stainless Steel Capillary Tubes and Tubing – Available Ex-Stock

316L Stainless Steel Capillary Tubes and Tubing – Available Ex-Stock

316Ti Stainless Steel Capillary Tubes and Tubing – Available Ex-Stock

321/321H Stainless Steel Capillary Tubes and Tubing – Available Ex-Stock

347/347H Stainless Steel Capillary Tubes and Tubing – Available Ex-Stock

Duplex Stainless Steel Pipes and Tubes – Available Ex-Stock

Super Duplex Stainless Steel Capillary Tubes and Tubing – Available Ex-Stock

Super Duplex Stainless Steel Capillary Tubes and Tubing – Available Ex-stock

Stainless Steel Capillary Tubes and Tubing Packing

Stainless Steel Capillary Tubes and Tubing is sleeved into plastic bag individually, pieces wrapped with water-proof material, bundled with nylon rope. Clear labels are tagged on the outside of the package for easy identification of the quantity and product I.D. Great care is taken during operation and transportation. Stainless Steel, Duplex Steel and Super Duplex Steel Pipe and Tubes packing will be according to international standard in bundles strapped by strips then into containers to avoid any damage.

Delivery: Within 10-25 days or asap if we have enough stock

Types of Packaging: - Bundles (hexagonal)

- Wooden Boxes

- Crates (steel/wooden)

- Special crates for U-Bend tubes with each radius separated

- Packaging for Stainless Steel Capillary Tubes and Tubin as per customer's requirements

Special Features: - Each bundle covered with plastic for protection against extreme weather.

- End of Stainless Steel Capillary Tubes and Tubin protected by plastic caps.

- Bundles strapped with plastic strips.

- Each radius of U-Bend tube separated by a separator.

- Packaging list (laminated) placed with box/crate.

We export Stainless Steel Capillary Tubes and Tubing to Saudi Arabia, Iran, Iraq, United Arab Emirates, Qatar, Bahrain, Oman, Kuwait, Turkey, Egypt, Yemen, Syria, israel, Jordan, Cyprus, Singapore, Malaysia, Indonesia, Thailand, Vietnam, South Korea, Japan, Sri Lanka, Maldives, Bangladesh, Mayanmar, Taiwan, Cambodia, Argentina, Bolivia, Brazil, Chile, Venezuela, Colombia, Ecuador, Guyana, Paraguay, Uruguay, United States Of America, Canada, Mexico, Panama, Costa Rica, Puerto Rica, Trinidad And Tobago, Jamaica, Bahamas, Denmark, Russia, Norway, Germany, France, Italy, United Kingdom, Spain, Ukraine, Netherland, Belgium, Greece, Czech Republic, Portugal, Hungary, Albania, Austria, Switzerland, Slovakia, Finland, Ireland, Croatia, Slovenia, Malta, Nigeria, Algeria, Angola, South Africa, Libya, Egypt, Sudan, Equatorial Guinea, The Republic Of Congo, Gabon, Europe, Africa, Asia, North America, South America, Middle East, Far East.etc.

Prosaic Steel and Alloys is a well known worldwide exporter of Stainless Steel Capillary Tubes and Tubing, Prosaic Steel and Alloys is committed to provide each and every customer with the highest standard of customer service. We deals in Stainless Steel Capillary Tubes and Tubing in India & Overseas, offering a wide range of Stainless Steel Capillary Tubes and Tubing.