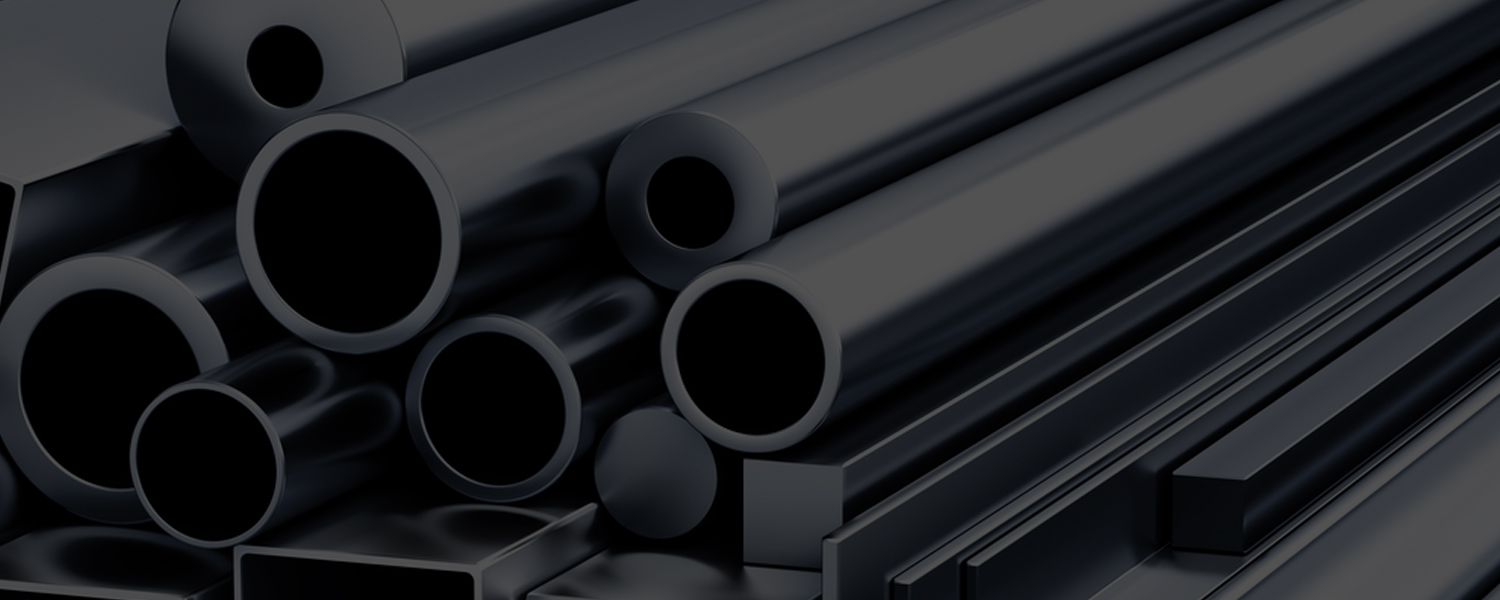

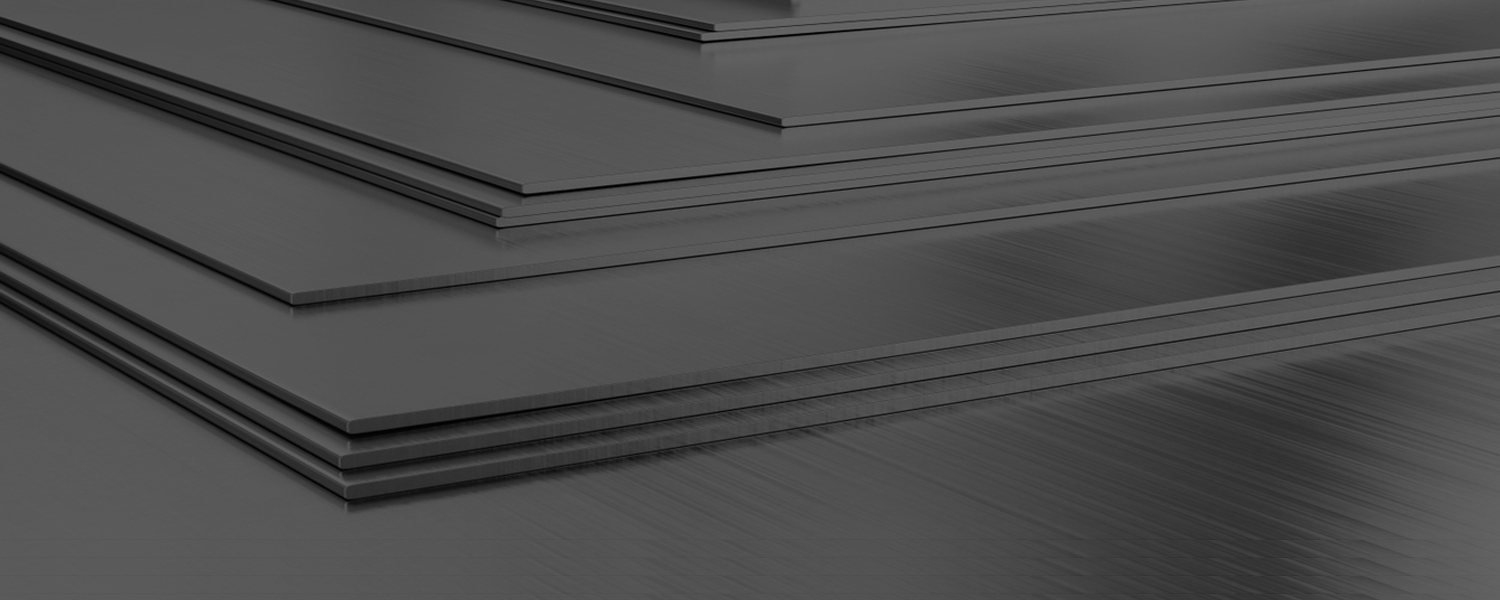

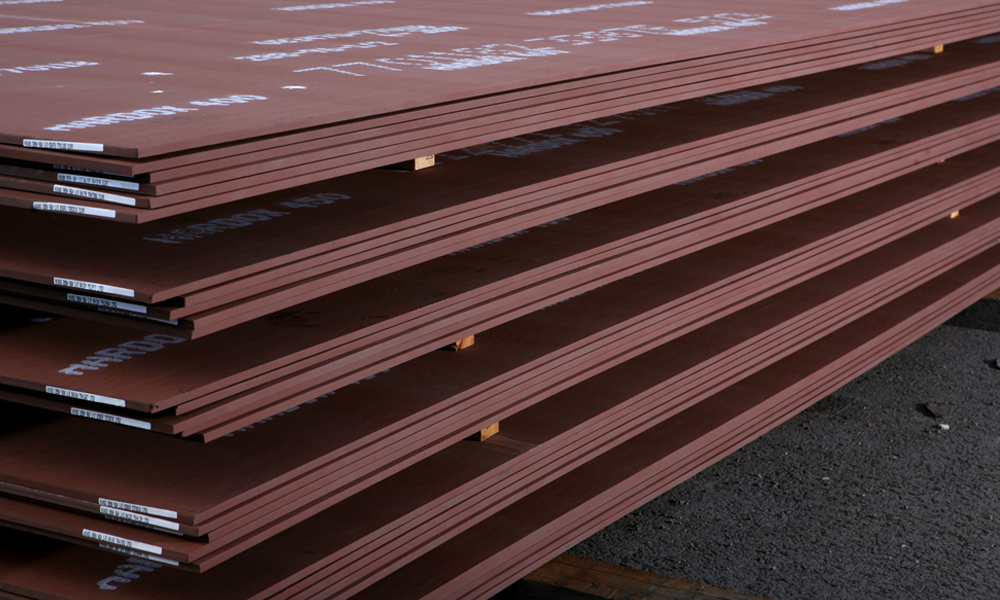

Stockholder, Supplier, Dealer, Distributor of Steel & Alloy Flat Products like Plates, Sheets, Coils, Profiles, Rings, Circles, Strips, Pata, Patti etc. SS 304 Pipes and ASTM A516 Grade 60/70 Our Hot Selling Products.

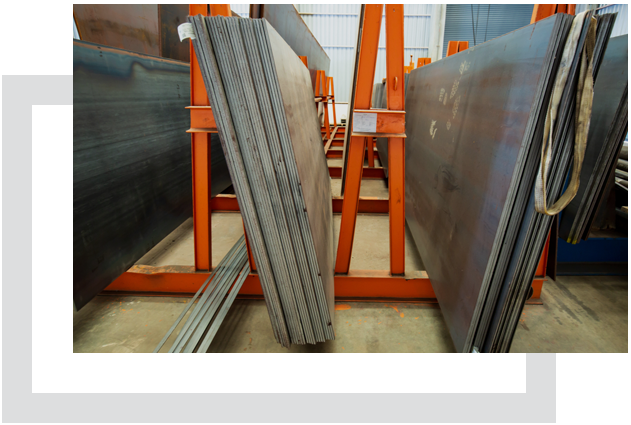

Prosaic Steel & Alloys, has identified India as a priority area for growth. As a part of this initiative, we had established state-of-the-art Storage Facility in India for Distribution Steel Flat Products like Plate, Coil, Sheet etc. to make available from world-class manufacturers to caters to the niche markets of almost all the emerging sectors like oil and gas, refineries, Petrochemicals, Real Estate, Process Industries, Power Plants, Mining and Water distribution.

Read More