State of Art Manufacturing Syphon Tube for Instrument, Switches, Transmitters, Pressure Gauges etc. in India.

SS 304 Syphon Tube and SS 316 Syphon Tube, Available Ready Stock of India Origin.

We Supply Best Quality Syphon Tube in Various Types like Pigtail Syphon, Q Shape Syphon, U Shape Syphon, Coil Form Syphon, Trumpet Shape Syphon, Q Type Pigtail Syphon 180 Degree, U Type Syphon 270 Degree, U Type Syphon 90 Degree, Q Type Syphon 90 Degree, Q Type Steam Syphon 90 Degree.

Prosaic Steel and Alloys is a leading manufacturer, supplier of comprehensive ranges of Syphon Tubes in Stainless steel, Carbon Steel, High Nickel Alloys. These tubes are manufactured using the premium quality of raw substances in a well equipped manufacturing unit. The offered ranges of tubes are used for the purpose of transferring several kinds of liquid from place to place ensuring smooth flow.

What is Syphon ?

A syphon can be defined as a simple tool which aids to protect the pressure gauge from hot temperature agents such as steam. In addition, it is effective in decreasing possibly destructing effects of speedy changes in pressure. Offered at economical prices, syphons enable builders of systems to employ a pressure sensor having a low temperature scale in high temperature functions. At the time of first installation, it is important to keep in mind that the syphon must be filled with water or any other appropriate separating channel.

Generally syphons are produced from carbon steel and endure temperature up to around 200 degrees Celsius. However, they can be fabricated from other materials too such as alloy steel and stainless steel with looped ports or butt weld. Additional coils can be attached and the tubes can be designed longer or shorter so as to meet unique requirements. Wound syphons are utilized for measuring steam pressure. They are usually connected between process taps and pressure gauges to avoid direct contact of live steam with instruments. Moreover, syphons possess good heat dissipation properties. They safeguard pressure gauges from high heat which can otherwise weaken their functioning.

Syphons Tube Specification

Syphon Material : SS 304, SS 304, SS 316, SS 316L, SS 310S, SS 317L, SS 6MO Etc.

Syphon Pipe :3/8" NB & 1/2” NB Pipe Sch 40 or 80 or 160

Connection Type : MxM, MxF, FxF

Thread Size : 3/8” or ½” BSP or NPT

Pressure Rating (Sch 40) : 135 bar at 400 deg C

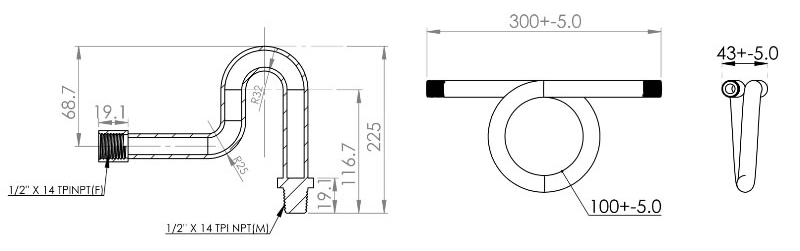

Type : Q type, O Type, Plate U Type, Straight U Type

Common Sizes of Stainless Steel 304 Syphon

Common size of Syphon U Type is SS 316 & SS 304 Syphons 1/4” NPTM x 1/4” NPTM, SCH 40

Common sizes of U Type Umbrella Syphon is SS 316 & SS 304 Syphons, U type, 1/4” NPTM x 1/4” NPTM, SCH 80

Common sizes of Syphons 90 Degree Pigtail Q-type is SS 316 & SS 304 Syphons 90 deg, Q-type 1/2" NPTM, Schedule 80

Common sizes of Pigtail Syphon Q Type 180 degrees is SS 316 & SS 304 Syphons 180 deg 1/2" NPTM x 1/2" NPTF, Schedule 80

Benefit of using Syphon Tube

-Syphons protect pressure measuring instruments from pulsations in the medium and from excessive heating

-Cooling element for fluids, gases and vapours in pressure measurement

-For direct mounting to the pressure connection of the pressure measuring instrument or to the shut-off device (stopcock or valve) mounted underneath

Types of Syphon Tubes

The pressure gauge syphon are mainly available in three types sequentially, coil syphon, pigtail syphon and U Type syphon and each is designed to match different application requirements of the industries using a pressure gauge.

Coil Syphon – Used Primarily For Horizontal Installations

The Coil shaped Syphon design is a reason for its recognition as a Coil Syphon Tube, which are extensively celebrated in the industries for its effectiveness in preventing pressure gauge from the effect of hot pressure media and reducing the effect of quick pressure surges. This coil syphon permits the formation of condensate that gathered inside the syphon and hence prevents direct contact of hot media with the pressure instruments. The excellent command of this coil syphon has made it widely popular as freeze protector.

Coil syphons are used significantly to protect pressure instruments, pressure gauge syphon, switches and transmitters straightly contacting with high temperature process fluids or vapours. This coil syphon is installed between process and pressure instruments and filled with condensation fluids that reduce process pulsation and function as heat dispensed and save instrument from working at unsafe temperatures.

Pig Tail Syphon – Used Primarily For Vertical Installations

The Pigtail Syphon is a looped pipe filled with water, designed profoundly to guard the internal parts of the steam pressure gauges from coming elevated steam temperature, as is one of the highly sensitive measuring instruments that demands significant caution in order to prevent the damage or destroy. This pigtail pressure gauge syphon permits changing of gas into a liquid by dissolving the hidden heat energy of steam and permit steam to condense, thus develop a loop seal of liquid that put off the conveyance of heat energy from the steam to the respective gauge. This pigtail syphon has well liked in the market for its impeccable operation and reliability measures that also widely accepted to protect the steam pressure gauge from any pressure surges in the system. During the application, it is recommended to fill the pigtail syphon with water or other parallel liquid substance former installation.

The Pigtail Syphon is installed between process and process instruments in order to protect the measuring instruments, including pressure instruments, gauges, switches and transmitter from the entering high temperature process vapours. Other than, this pigtail syphon known to be effective in preventing the instrument to work at hazardous temperature. This pigtail syphon is being prominent in the industries for its influential functioning all through its life and ensuring safety of the respective instrument.

U Type Syphon – Used Primarily For Horizontal Installations

The U shape of the pipe connected between the pressure gauge and process makes it renowned as the U type syphon in the industries. This U type Syphon is globally accepted for its outstanding performance, used widely to prevent the entering of hot media into the measuring instrument hence protect the instrument from the damage. This U types syphon permits condensate to form and be accumulated inside the syphon that prevents direct contacting of the hot vapors with the pressure instrument. However, it is counseled filling the U type syphon together with a cooling separating liquid ahead of starting the pressure line. This U type syphon is also being prominent in the heating dispersion that prevents instrument to work at hazardous temperature.

The U type syphon is equipped between process and process instruments to ensure safety of the pressure instruments, gauges, switches and transmitter from the entering high temperature vapor. This U type syphon intensifying popularity in the diverse industries is an evidence of its worthiness, which is also being used to avoid instrument to work at dangerous temperature.

- Pigtail Syphon

- U Shape Syphon

- U Type Syphon 270 Degree

- U Type Syphon 90 Degree

- Syphon U Type Male X Male

- Syphon U Type Male X Female

- Syphon Umbrella Type

- Syphon Umbrella Type Male X Male

- Syphon Umbrella Type Male X Female

- Q Shape Syphon

- Q Type Syphon 90 Degree

- Q Type Steam Syphon 90 Degree

- Q Type Pigtail Syphon 180 Degree

- Coil Form Syphon

- Trumpet Type Syphon

Stainless Steel 310s Q Type, Stainless Steel 317h U Type Syphon Tube Manufacturer, Ss 316Ti U Type 270 Degree Syphon Tube, Stainless Steel 321h Q-Type 90 Degree Syphon Tube Suppliers, ,Stainless Steel 310h Steam Syphon Stockist, Ss 310 Syphon Tube in India, Stainless Steel 316ti Pigtail Syphon Pipes Stockholder, Ss 310s Syphon Pipe Suppliers, Ss 347H Q Type Syphon Exporter in India.

304 Syphon Material of Construction

| Stainless Steel | ASME / ASTM SA / A312 SA / A213 304, 304L, 316, 316L, 304/304L, 304H, 316H, 316/316L, 321, 330, 347, 309/S, 310/S, 317/L, 333, 410/S, DIN 1.4301, DIN1.4306, DIN 1.4401, DIN 1.4404 |

| Monel Alloys | Monel 400, Monel K500, Monel R-405 |

| Nickel Alloys | Nickel 200, Nickel 201 |

| Inconel Alloys | Inconel 600, Inconel 601, Inconel 625, Inconel 718 |

| Incoloy Alloys | Incoloy 800, Inconel 800H, 800HT |

| Hastelloy Alloys | Hastelloy B2, Hastelloy B3, Hastelloy C22, Hastelloy C276, Hastelloy X |

| Titanium Alloys | Gr1, Gr2, Gr3, Gr5, Gr7, Gr11 |

| Carbon Steel | ASTM A 106, ASTM A333 |

| Duplex and Super Duplex Stainless Steel | ASTM / ASME A/SA790 UNS S31803, UNS S32750, UNS S32760 |

| Alloy Steel (Chrom Moly Alloys) | ASTM SA 335 P5, P9, P11, P22, P91 |

Standard Design and Dimension

| MATERIAL | TUBE / PIPE SIZE | DI | SCH 40 | SCH 80 | SCH 160 | SCH XXS | ||||

| PLAIN x THREADED | DIA | LENGTH L1 |

PRESSURE Kg/cm2 |

LENGTH L1 |

PRESSURE Kg/cm2 |

LENGTH L1 |

PRESSURE Kg/cm2 |

LENGTH L1 |

PRESSURE Kg/cm2 |

|

| A 106 Gr. B | 1/4" | 4" | 175 | 300 | 175 | 600 | 175 | 900 | 175 | 1500 |

| SS 316/316L | 1/4" | 4" | 175 | 300 | 175 | 600 | 175 | 900 | 175 | 1500 |

| SS 304 | 1/2" | 6" | 175 | 300 | 175 | 600 | 175 | 900 | 175 | 1500 |

| A335 Gr. P11 | 1/2" | 6" | 175 | 300 | 175 | 600 | 175 | 900 | 175 | 1500 |

Materials: carbon steel, SS304 and SS316 Connected between the pressure gauge and process in applications where high temperature vapors or fluids are present or temperature above 65 degrees Celsius Acts as cooling coil and protects the gauge from high temperature vapors, also syphons help in dissipating heat

Tube types: U type, Q TYPE type (pigtail and coil type)

Operating temperature:

Steel: 210kg/cm2 at 20°C

Stainless steel: 260kg/cm2 at 20°C

S/W, Screwed NPT, BSP, Male/ Female, Swivel type

Stainless Steel 304 Syphon Tube Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

|---|---|---|---|---|---|---|---|---|---|---|

| 304 | min. | - | - | - | - | - | 18.0 | - | 8.0 | - |

| max. | 0.08 | 2.0 | 0.75 | 0.045 | 0.030 | 20.0 | 10.5 | 0.10 | ||

| 304L | min. | - | - | - | - | - | 18.0 | - | 8.0 | - |

| max. | 0.030 | 2.0 | 0.75 | 0.045 | 0.030 | 20.0 | 12.0 | 0.10 | ||

| 304H | min. | 0.04 | - | - | - | - | 18.0 | - | 8.0 | - |

| max. | 0.10 | 2.0 | 0.75 | 0.045 | 0.030 | 20.0 | 10.5 | |||

316 Syphon Tube Chemical Composition

| Grade | C | Mn | Si | P | S | Cr | Mo | Ni | N | |

| 316 | Min | - | - | - | 0 | - | 16.0 | 2.00 | 10.0 | - |

| Max | 0.08 | 2.0 | 0.75 | 0.045 | 0.03 | 18.0 | 3.00 | 14.0 | 0.10 | - |

| 316L | Min | - | - | - | - | - | 16.0 | 2.00 | 10.0 | - |

| Max | 0.03 | 2.0 | 0.75 | 0.045 | 0.03 | 18.0 | 3.00 | 14.0 | 0.10 | - |

| 316H | Min | 0.04 | 0.04 | 0 | - | - | 16.0 | 2.00 | 10.0 | - |

| max | 0.10 | 0.10 | 0.75 | 0.045 | 0.03 | 18.0 | 3.00 | 14.0 | - | - |

We export Syphon Tube to Saudi Arabia, Iran, Iraq, United Arab Emirates, Qatar, Bahrain, Oman, Kuwait, Turkey, Egypt, Yemen , Syria, israel, Jordan, Cyprus, Singapore, Malaysia, Indonesia, Thailand, Vietnam, South Korea, Japan, Sri Lanka, Maldives, Bangladesh, Mayanmar, Taiwan, Cambodia, Argentina, Bolivia, Brazil, Chile, Venezuela, Colombia, Ecuador, Guyana, Paraguay, Uruguay, United States Of America, Canada, Mexico, Panama, Costa Rica, Puerto Rica, Trinidad And Tobago, Jamaica, Bahamas, Denmark, Russia, Norway, Germany, France, Italy, United Kingdom, Spain, Ukraine, Netherland, Belgium, Greece, Czech Republic, Portugal, Hungary, Albania, Austria, Switzerland, Slovakia, Finland, Ireland, Croatia, Slovenia, Malta, Nigeria, Algeria, Angola, South Africa, Libya, Egypt, Sudan, Equatorial Guinea, The Republic Of Congo, Gabon, europe, Africa, Asia, North America, South America, Middle East, Far East.etc

Prosaic Steel and Alloys is a well known worldwide exporter of Syphon, is committed to provide each and every customer with the highest standard of customer service. We deals in Syphon Tube Supplier in India & Overseas, offering a wide range of SS Syphons

Prosaic Steel and Alloys is Leading Manufacturer, Distributior, Exporter, Stockholder and Supplier of Syphon Tube in Unites States of America (USA), Saudi Arabia, Iran, Iraq, Unites Arab Emirates (UAE), Turlkey, Italy, Germany etc.

SS 304 Syphon Tube, SS 316 Syphon Tube, syphon tube in co2 bottle, syphon tube for pressure gauge, siphon tube price, syphon tube for wine, syphon tube for fish tank, siphon principle, syphon tube co2 cylinder, siphon pipe for aquarium, how does a pressure gauge siphon work, pressure gauge with syphon and valve, snubber for pressure gauge, internal siphon gauge, types of syphon, pressure gauge pigtail purpose, steam pressure gauge, steam pressure gauge installation