Forged Pipe Fittings Socket Weld (S/W) & Screwed (SCRD)

Forged Pipe Fittings - Socket Weld Fittings, Threaded Fittings, Screwed Fittings

Forged Pipe Fittings – Stainless Steel, Alloys Steel, Carbon Steel, Duplex Steel, Copper Alloy and Nickel Alloy

Manufacture and Exporter of Forged Pipe Fittings such as 90 Degree Elbow (Long Radius / Short Radius), Equal Tee, 45 Degree Elbow (Long Radius/Short Radius), Manufacturer and Exporter of Forged fitting’s such as 90 Degree Elbow (Long Radius / Short Radius), Equal Tee, 45 Degree Elbow (Long Radius/Short Radius), Reducing Tee, Round Cap, Concentric Reducer, Eccentric Reducer Stub end

Seamless & welded long radius & short radius elbow 90 deg, long radius elbow 45 deg, long radius & short radius elbow 180 deg (return bend), reducing elbow, equal tee, unequal tee, crosses, concentric reducer, eccentric reducer, long stubend, short stubend, collar, pipe cap, long radius bends R = 3D, 5D, 6D, 8D, 10D & 20D in 15 deg, 30 deg, 60 deg & 90 deg and drawing based butt weld fittings

Carbon Steel Pipe Fittings

Carbon Steel Pipe Fittings

We specialize in manufacturing a custom made array of carbon steel pipe fittings made from premium quality carbon and alloy steel. Available at most competitive prices, these carbon steel pipe fittings are offered in the following specifications:

Standards:

ASTM A105/ A694 F42/ 46/ 52/ 56/ 60/ 65/ 70/ A350 LF3/ A350 LF2

Alloy Steel:

ASTM / ASME A 182 GR F5, F9, F11, F12, F22, F91.

Types:

Weld-neck, blind, lap joint, ring joint, long weld-neck, deck flange

Class

150#, 300#, 400#, 600#, 900#, 1500# & 2500#

Stainless Steel & Duplex Steel Pipe Fittings

Stainless Steel & Duplex Steel Pipe Fittings

Widely applicable in varied industrial applications, our gamut of duplex steel pipe fittings is manufactured using high grade stainless steel and duplex steel. These duplex steel pipe fittings are widely appreciated by our global clients owing to their features of zero-defects and superior performance. These duplex steel pipe fittings can be availed by our clients in the following custom made specifications:

Range:

5 mm NB upto 1200 mm NB in Schedule 5S, 10S, 10, 20, 40S, 40, STD, 60, 80S, 80, XS, 100, 120, 140, 160

STAINLESS STEEL

ASTM / ASME SA 182 F 304, 304L, 304H, 309H, 310H, 316, 316H, 316L, 316 LN, 317, 317L, 321, 321H, 347, 347 H

DUPLEX STEEL

ASTM / ASME SA 182 F 44, F 45, F51, F 53, F 55, F 60, F 61.

Copper Alloy Pipe Fittings

Copper Alloy Pipe Fittings

The forged fittings made of nickel and copper alloy provided by us exhibits all the requisite characteristics like durability, corrosion resistance and ability to withstand temperature variations. The grades and standards of nickel alloy fittings and copper alloy pipe fittings are:

- ASTM / ASME SB 564 UNS 2200 (NICKEL 200)

- UNS 4400 (MONEL 400)

- UNS 8825 INCONEL (825)

- UNS 6600 (INCONEL 600)

- UNS 6601 (INCONEL 601)

- UNS 6625 (INCONEL 625)

- UNS 10276 (HASTELLOY C 276 )

- ASTM / ASME SB 160 UNS 2201 (NICKEL 201)

- ASTM / ASME SB 472 UNS 8020 (ALLOY 20 / 20 CB 3)

We offer our range of copper alloy fittings in the following grade specifications:

- ASTM / ASME SB 61 UNS NO. C 92200

- ASTM / ASME SB 62 UNS NO. C 83600

- ASTM / ASME SB 151 UNS NO. 70600, 71500, C 70600 (CU -NI- 90/10), C 71500 (CU -NI- 70/30)

- ASTM / ASME SB 152 UNS NO C 10100, C 10200, C 10300, C 10800, C 12000, C 12200

Forged Elbow (90°)

Pipe elbow fittings is a very important pipe fitting. When we talk about a pipe elbow, it means a length of pipe with a sharp bend in it. Pipe elbows are fitting accessories which are used widely in various industrial sectors in pipe fitting. A pipe elbow is frequently used in pressurized applications and is available in various shapes and sizes for use in different applications. A pipe elbow is a fitting installed between two lengths of pipe or tube allowing a change of direction, usually in the 90° or 45° direction.

Prosaic Steel & Alloys manufactures pipe fitting devices which are bent in such a way to produce some degree (90, 45, 180 degree) changes in the direction of flow of the content in the pipe. Elbows are manufactured to meet different specifications, in terms of size and diameter. Prosaic Steel & Alloys manufactures & supplies high quality elbows that can be used for various applications. Our elbows are tested and verified for durability, accuracy and precision.

Prosaic Steel & Alloys manufactures forged, seamless & welded elbows (pipe fitting) of types 90° Elbows, 90° Elbow, 45° Elbows, 180° Elbow of socket weld, threaded type to ANSI B 16.9 from classes 2000 to 9000 and Schedules from 10 to 160.

Prosaic Steel & Alloys manufactures elbow (pipefitting) accordance with BS standard from classes 2000 to 9000 lbs, Schedule 10 to 160.

Prosaic Steel & Alloys designs & manufactures elbows (pipe fittings) of special type made according to drawing on request.

Grades:

Nickel Alloy

ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

Stainless Steel

ASTM / ASME SA 182 GR WP "S" / "W" / " WX" 304, 304L, 304H, 304N, 304LN, 309, 310H, 316, 316H, 317, 317L, 321, 321H, 347, 347 H.

Duplex Steel

ASTM / ASME SA 182 UNS NO.S31803, S32205, S32550, S32750, S32760.

Carbon Steel

ASTM / ASME A 105 WPB, WPC

ASTM / ASME A 105 WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

Alloy Steel

RANGE :

Forged Fittings 15 NB to 100 NB in 3000 LBS, 6000 LBS, 9000 LBS available with NACE MR 01-75.

Outlet’s ¼” to 24” in 3000 LBS, 6000 LBS, 9000 LBS available with NACE MR 01-75. (We also make customized fitting as per drawn)

TYPE :

Socket Weld (S/W) & Screwed (SCRD)

Manufacturing standard: ANSI, JIS, DIN, EN, API 5L, etc.

Bending Angle: Degree 15, 30, 45, 60, 90, 135, 180 and also could manufacture according the angles given by the clients.

end Bevel: According to the bevel of welding Pipe fittings construction

Surface treatment: Shot blasted, rust-proof black oil

Forged elbow (45°)

Owing to offer quality products, we are involved in making of elbow 45 degree for our customers. These pipe fittings offer amazing functionality. Stainless steel, alloy steel, nickel alloys are used for crafting these pipe fittings. Our Elbow (45°) pipe fitting is offered at market leading rates.

|

|

RANGE :

Forged Fittings 15 NB to 100 NB in 3000 LBS, 6000 LBS, 9000 LBS available with NACE MR 01-75.

Outlet’s ¼” to 24” in 3000 LBS, 6000 LBS, 9000 LBS available with NACE MR 01-75. (We also make customized fitting as per drawn)

TYPE :

Socket Weld (S/W) & Screwed (SCRD)

Material Type:

Stainless Steel, Alloy Steel and Carbon Steel

Nickel Alloys

Duplex

Grades:

Grades:

Nickel Alloy

ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

Stainless Steel

ASTM / ASME SA 182 GR WP "S" / "W" / " WX" 304, 304L, 304H, 304N, 304LN, 309, 310H, 316, 316H, 317, 317L, 321, 321H, 347, 347 H.

Duplex Steel

ASTM / ASME SA 815 UNS NO.S31803, S32205, S32550, S32750, S32760.

Carbon Steel

ASTM / ASME A 105 WPB, WPC

ASTM / ASME A 860 WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

Alloy Steel

ASTM / ASME A 105 WP1, WP5, WP 9, WP11, WP12, WP22, WP23, WP91

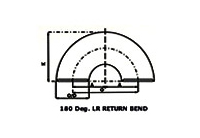

Elbow (180°)

We have earned prominent name in designing of Elbow (180°) fitting. These pipe fittings serve wide range of functionalities in outstanding way. The Elbow 180 degree is crafted with great precision by our experienced staff. We provide best rates for elbow 180 degree.

|

|

RANGE :

Forged Fittings 15 NB to 100 NB in 3000 LBS, 6000 LBS, 9000 LBS available with NACE MR 01-75.

Outlet’s ¼” to 24” in 3000 LBS, 6000 LBS, 9000 LBS available with NACE MR 01-75. (We also make customized fitting as per drawn)

TYPE :

Socket Weld (S/W) & Screwed (SCRD)

Material Type:

Stainless Steel, Alloy Steel and Carbon Steel

Nickel Alloys

Duplex

Grades:

Nickel Alloy

ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

Stainless Steel

ASTM / ASME SA 182 GR WP "S" / "W" / " WX" 304, 304L, 304H, 304N, 304LN, 309, 310H, 316, 316H, 317, 317L, 321, 321H, 347, 347 H.

Duplex Steel

ASTM / ASME SA 815 UNS NO.S 31803, S 32205, S 32550, S 32750, S 32760.

Carbon Steel

ASTM / ASME A 105 WPB, WPC

ASTM / ASME A 860 WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

Alloy Steel

ASTM / ASME A 182 F1, WP 5, F9, F11, F12, F22, F 911.

Forged equal Tee and Cross

Pipe Tee is a type of pipe fitting which is T-shaped having two outlets, at 90° to the connection to the main line. It is a short piece of pipe with a lateral outlet. Pipe Tee is used to connect Pipelines with a pipe at a right angle with the line. Pipe Tees are widely used as pipe fittings. They are made of various materials and available in various sizes and finishes. Pipe tees are extensively used in pipeline networks to transport two-phase fluid mixtures.

Pipe Tee is a type of pipe fitting which is T-shaped having two outlets, at 90° to the connection to the main line. It is a short piece of pipe with a lateral outlet. Pipe Tee is used to connect Pipelines with a pipe at a right angle with the line. Pipe Tees are widely used as pipe fittings. They are made of various materials and available in various sizes and finishes. Pipe tees are extensively used in pipeline networks to transport two-phase fluid mixtures.

Prosaic Steel & Alloys manufactures a wide range of tees (pipefitting) made of exotic metals, nickel, nickel alloys, Stainless Steel etc., of various grades. Tees (branch outlets) are manufactured as Equal tees and Reducing tees. Equal tees are exactly that, all three ends are of the same size. Reducing tees come with a combination of different outlet sizes.

Prosaic Steel & Alloys manufactures & supplies high quality tees ( pipe fitting ) that can be used for various applications. Our tees are tested and verified for durability, accuracy and precision.

Prosaic Steel & Alloys manufactures forged [ socket weld tee, forged threaded tees ], seamless & weldedtees of types equal tee, reducing tees to ANSI B 16.5 from classes 2000 to 9000 and Schedules from 10 to 160 .

Prosaic Steel & Alloys manufactures tees accordance with BS standard from classes 2000 to 9000 lbs, Schedule 10 to 160.

Prosaic Steel & Alloys designs & manufactures tees (pipe fittings) of special type made according to drawing on request.

RANGE :

Forged Fittings 15 NB to 100 NB in 3000 LBS, 6000 LBS, 9000 LBS available with NACE MR 01-75.

Outlet’s ¼” to 24” in 3000 LBS, 6000 LBS, 9000 LBS available with NACE MR 01-75. (We also make customized fitting as per drawn)

TYPE :

Socket Weld (S/W) & Screwed (SCRD)

Form : Equal Tee, Reducing Tee, Barred Tee, Lateral Tee

Material Type:

Stainless Steel

ASTM A182 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

Carbon Steel

ASTM A 105 WPB, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

Low Temperature Carbon Steel

ASTM A420 WPL3 / A420WPL6

Alloy Steel

ASTM / ASME A/SA 105 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

Duplex Steel

ASTM A 815 UNS NO S 31803, S 32205.

Nickel Alloy

ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

VALUE ADDED SERVICES

- Hot Dip Galvanizing

- Epoxy Coating

- Electro polish

TEST CERTIFICATE

Mill Test Certificate as per EN 10204 / 3.1B

Forged Pipe Reducers

Pipe reducer is tube fittings that are widely used in a number of industries in order to providing greatest connection flexibility in connecting fractional tubes in various installations. Pipe reducer is a kind of pipe fitting that joins two pipes of different diameter. The pipe reducers are available in a range of materials depending on the end use of the products and these fittings are manufactured in inch and metric size.

Pipe reducers are special type of tube fittings that are commonly used in the demanding environments of chemical and power plants. They provide a highly reliable, sturdy and tight integral line system and these types of pipe fittings remain unaffected by shock, vibration or thermal distortion. These Pipe fittings are very easy to install and they resist leakage due to thermal or pressure cycling. These reducers are sometimes chrome or nickel coated to prevent corrosion and increase the life of the product.

Prosaic Steel & Alloys manufactures reducers (pipe fitting) to reduce the diameter of the suction piping to fit the pump intake, thus used to join two pipes of different sizes. Reducers are available in both eccentric and concentric designs. Concentric or eccentric reducers are used to properly reduce into and out of circulating pumps.

The various advantages include keeping big pipes and small pipes together as well as reducing noise and vibration at the same time. Our reducers are tested and verified for durability, accuracy and precision.

Prosaic Steel & Alloys manufactures forged, seamless & welded reducers ( pipe fitting ) of types concentric reducer, eccentric reducers to ANSI B 16.5 from classes 2000 to 9000 and Schedules from 10 to 160 .

Prosaic Steel & Alloys manufacture reducers accordance with BS standard from classes 2000 to 9000 lbs, Schedule 10 to 160 .

Prosaic Steel & Alloys designs & manufactures reducers (pipefitting) of special type made according to drawing on request.

RANGE :

Forged Fittings 15 NB to 100 NB in 3000 LBS, 6000 LBS, 9000 LBS available with NACE MR 01-75.

Outlet’s ¼” to 24” in 3000 LBS, 6000 LBS, 9000 LBS available with NACE MR 01-75. (We also make customized fitting as per drawn)

Form : Eccentric Reducer, Concentric Reducer

Material Type:

Stainless Steel

ASTM A182 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

Carbon Steel

ASTM A 105 WPB, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

Low Temperature Carbon Steel

ASTM A420 WPL3 / A420WPL6

Alloy Steel

ASTM / ASME A/SA 105 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

Duplex Steel

ASTM A 815 UNS NO S 31803, S 32205

Nickel Alloy

ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

VALUE ADDED SERVICES

- Hot Dip Galvanizing

- Epoxy Coating

- Electro polish

TEST CERTIFICATE

Mill Test Certificate as per EN 10204 / 3.1B

Forged Caps and Stub Ends

Pipe caps act as protective device and are designed to protect pipe ends of various shapes. The main purpose of using pipe caps is to waterproof the connections. They are also used to close the ends of hydraulic or pneumatic Pipes and tubes. They are used in the plumbing apparatus of domestic, commercial and industrial water supply lines, machinery and processing equipment etc. They are also fitted on water pump lines with the sole purpose of removing air blocks. Pipe caps are highly demanded as an important category of pipe fittings.

Pipe caps act as protective device and are designed to protect pipe ends of various shapes. The main purpose of using pipe caps is to waterproof the connections. They are also used to close the ends of hydraulic or pneumatic Pipes and tubes. They are used in the plumbing apparatus of domestic, commercial and industrial water supply lines, machinery and processing equipment etc. They are also fitted on water pump lines with the sole purpose of removing air blocks. Pipe caps are highly demanded as an important category of pipe fittings.

Prosaic Steel & Alloys manufactures a wide range of caps ( pipefitting) made of materials - exotic metals, nickel, cupro-nickel, Stainless Steel etc., of various grades. Prosaic Steel & Alloys manufactures & supplies high quality cap (pipe fitting) that can be used for various applications. Our caps(pipefittings) are tested and verified for durability, accuracy and precision.

Prosaic Steel & Alloys manufactures forged & seamless caps(pipefitting) of types including socket weld cap, threaded cap to ANSI B 16.5 from classes 2000 to 9000 and Schedules from 10 to 160.

Prosaic Steel & Alloys manufacture forged socketweld & threaded caps, seamless cap accordance with BS standard from classes 2000 to 9000 lbs, Schedule 10 to 160 .

Prosaic Steel & Alloys also design & manufacture caps (pipe fittings) of special types made according to drawing on request.

Stub Ends are fittings used in place of welded flanges where rotating back up flanges are desired. They are also called Lap Joints and Vanstone Flared Laps. A rotating back up flange seats itself against the back surface of the Stub End. When bolts are added, the clamping action of the bolts presses the rotating back up flange against the back of the Stub End. The gasket surface of the Stub End then presses against a gasket and another gasket surface providing joints like standard flange joints. The seal is made by the gasket surface of the stub end alone, the flange only provides the clamping pressure on the joint.

Stub Ends are fittings used in place of welded flanges where rotating back up flanges are desired. They are also called Lap Joints and Vanstone Flared Laps. A rotating back up flange seats itself against the back surface of the Stub End. When bolts are added, the clamping action of the bolts presses the rotating back up flange against the back of the Stub End. The gasket surface of the Stub End then presses against a gasket and another gasket surface providing joints like standard flange joints. The seal is made by the gasket surface of the stub end alone, the flange only provides the clamping pressure on the joint.

Our high quality stub ends (Butt weld fittings) are tested and verified for durability, accuracy and precision. The stub ends are manufactured in all standard dimensions. The stub ends are provided with a standard weld bevel and can be available in squared, flanged, victaulic and threaded ends. We offer stub ends at highly competitive prices.

Prosaic Steel & Alloys manufactures a wide range of stub ends (pipefitting) made of materials - exotic metals, nickel, cupro-nickel, Stainless Steel etc., of various grades. Prosaic Steel & Alloys manufactures & supplies high quality stub ends (pipe fittings) that can be used for various applications. Our stub ends are tested and verified for durability, accuracy and precision.

Prosaic Steel & Alloys manufactures seamless stub ends of long & short radius to MSS and ANSI B 16.9 standard from Schedules 10 to 160.

Prosaic Steel & Alloys designs & manufactures subtends (pipe fitting) of special type made according to drawing on request.

RANGE :

Forged Fittings 15 NB to 100 NB in 3000 LBS, 6000 LBS, 9000 LBS available with NACE MR 01-75.

Outlet’s ¼” to 24” in 3000 LBS, 6000 LBS, 9000 LBS available with NACE MR 01-75. (We also make customized fitting as per drawn)

Type : End Cap ,Stub End

Material Type:

Stainless Steel

ASTM A182 WP Gr. 304, 304H, 309, 310, 316, 316L, 317L, 321, 347, 904L

Carbon Steel

ASTM A 105 WPB, WPBW, WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

Low Temperature Carbon Steel

ASTM A420 WPL3 / A420WPL6

Alloy Steel

ASTM / ASME A/SA 105 Gr. WP 1, WP 5, WP 9, WP 11, WP 12, WP 22, WP 91

Duplex Steel

ASTM A 815 UNS NO S 31803, S 32205.

Nickel Alloy

ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

VALUE ADDED SERVICES

- Hot Dip Galvanizing

- Epoxy Coating

- Electro polish

TEST CERTIFICATE

Mill Test Certificate as per EN 10204 / 3.1B

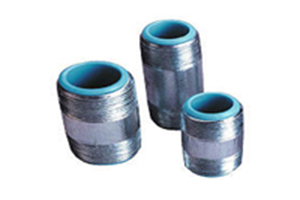

Forged Steel Nipples

A Pipe nipple is a length of straight pipe with male threads on both ends. It is one of the most popular category of pipe fittings. It is a connector or a coupling threaded on both ends. Pipe nipples are used to allow plumbing to be connected to a water heater or other plumbing. They are used to fit straight end hose or pipe. A combination of pipe nipples are recommended for low-pressure discharge and suction service for various compatible liquids and not for compressible products like air, nitrogen or steam.

A Pipe nipple is a length of straight pipe with male threads on both ends. It is one of the most popular category of pipe fittings. It is a connector or a coupling threaded on both ends. Pipe nipples are used to allow plumbing to be connected to a water heater or other plumbing. They are used to fit straight end hose or pipe. A combination of pipe nipples are recommended for low-pressure discharge and suction service for various compatible liquids and not for compressible products like air, nitrogen or steam.

The working pressure of pipe nipples will vary with the size and construction of the pipe, the type and number of clamps used, clamp placement, proper installation of clamps, temperature and product being conveyed. Pipe nipples are available in the widest variety of wall thicknesses and materials in the industry.

We manufactures a wide range of nipples (pipe fitting) made of materials such as exotic metal, nickel, nickel alloys, cupronickel, Stainless Steel etc., of various grades. Steel Tubes India manufactures & supplies high quality nipples (pipefitting) that can be used for various applications. Our nipples are tested and verified for durability, accuracy and precision.

Steel Tubes India manufactures forged socket welding nipple and forged threaded nipples to ANSI, BS, SAE & (swaged nipple ) MSS standards from Classes 2000 lbs to 9000 lbs

RANGE :

Forged Fittings 15 NB to 100 NB in 3000 LBS, 6000 LBS, 9000 LBS available with NACE MR 01-75.

Outlet’s ¼” to 24” in 3000 LBS, 6000 LBS, 9000 LBS available with NACE MR 01-75. (We also make customized fitting as per drawn)

Form : Pipe Nipple, Hex Nipple, Swage Nipple, Barrel Nipple

Grades:

Nickel Alloy

ASTM / ASME SB 336 UNS 2200 ( NICKEL 200 ), UNS 2201 (NICKEL 201 ), UNS 4400 (MONEL 400 ), UNS 8020 ( ALLOY 20 / 20 CB 3, UNS 8825 INCONEL (825), UNS 6600 (INCONEL 600 ), UNS 6601 ( INCONEL 601 ), UNS 6625 (INCONEL 625), UNS 10276 ( HASTELLOY C 276 )

Stainless Steel

ASTM / ASME SA 182 GR WP "S" / "W" / " WX" 304, 304L, 304H, 304N, 304LN, 309, 310H, 316, 316H, 317, 317L, 321, 321H, 347, 347 H.

Duplex Steel

ASTM / ASME SA 815 UNS NO.S 31803, S 32205, S 32550, S 32750, S 32760.

Carbon Steel

ASTM / ASME A 105 WPB, WPC

ASTM / ASME A 860 WPHY 42, WPHY 46, WPHY 52, WPH 60, WPHY 65 & WPHY 70.

Alloy Steel

ASTM / ASME A 105 WP1, WP5, WP 9, WP11, WP12, WP22, WP23, WP91

FORGED SOCKETWELD FITTINGS

A socket weld is a pipe attachment detail in which a pipe is inserted into a recessed area of a valve or fitting, and then fillet welded between its outside diameter and the fitting end. Generally used for piping whose nominal diameter is 4 inches (100 mm) or smaller.

We provide complete range of Socket Weld Pipe Fittings in the international market. We have carved a niche in the market as one of the reliable CS Pipe Fittings Exporters from India. Our range consists of full socket, half socket, welding nipple, barrel nipple, parallel nipple, bend 90°, hexagon nipple, elbow 90°, elbow 45°, reducing elbow, equal tee, reducing tee, reducer cross, Y-piece, conical union, hose union, elbow union, etc. We can offer Carbon Steel Socket Weld Fittings to the following specification with pressure ratings of 3000lbs, 6000lbs, 9000lbs.

Technical Specifications:-

- Shapes : Tee, Elbow, Coupling, Cap, Reducer, Cross, Reducing, Coupling

- Size : 1/2”-4”

- Class : #2000, #3000, #6000, #9000#

Grades :-

- ASTM/ASME SA 105

- ASTM/ASME SA 350 LF2/LF3 ETC

- ASTM /ASME SA182 : F304/ F304L/ F304H/ F316/ F316L/ F317/ F317L/ F321/ F310/ F347/F904L.

- ASTM/ASME SA182 : F1/F5/F9/F11/F22/F91.ETC

- HEAVY METAL ALLOYS : Monel, Nickel, Inconel, Hastealloy, Copper, Brass, Bronze, Titanium, Tantalum, Bismuth, Aluminum, Duplex Steel, Super Duplex Steel, Zinc, Lead.

- CHROME-MOLY grades of F5, F9, F11, F22, Plus Duplex, and Exotic Alloy.

- OUR socket weld fittings range from 1/8”-4”

Forged Socket Welding Fittings (ASME B 16.11-2001)

Forged Threaded Fittings

It is a UK standard of pipe fitting also called as, these threaded fittings, threaded fittings, steel hreaded fittings, steel threaded pipe fittings are used to achieve pressure tight joints by threads alone. Functionally superior in nature, these threaded fittings, steel threaded fittings, pipe fittings, steel threaded pipe fittings can withstand high pressure while maintaining smooth flow of liquid by preventing leakage. These threaded fittings are made of threaded stainless steel, socket weld stainless steel or higher alloys that are long lasting and rust free.

Range - 1/8”-24”SCH 10S-SCH XXS

Grades :-

- ASTM/ASME SA 105

- ASTM/ASME SA 350 LF2/LF3 ETC

- ASTM /ASME SA 182: F304/ F304L/ F304H/ F316/ F316L/ F317/ F317L/ F321/ F310/ F347/F904L.

- ASTM/ASME SA 182 : F1/F5/F9/F11/F22/F91.ETC

- HEAVY METAL ALLOYS: Monel, Nickel, Inconel, Hastealloy, Copper, Brass, Bronze, Titanium, Tantalum, Bismuth, Aluminum, Duplex Steel, Super Duplex Steel, Zinc, Lead.

- CHROME-MOLY grades of F5, F9, F11, F22, Plus Duplex, and Exotic Alloy.

Forged Threaded Fittings (ASME B 16.11-2001)