ASTM B564 Monel 400 Flanges | ASME SB564 Monel 400 Flanges | Alloy 400 Slip On Flanges | UNS NO4400 Slip On Flanges

Monel 400 Slip On Flanges | ASTM B564 Monel 400 Flanges | ASME SB564 Monel 400 Flanges | UNS NO4400 Slip On Flanges | Alloy 400 Slip On Forged Flanges

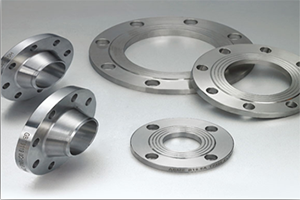

High Quality ASTM B564 Monel 400 Slip On Flanges Manufacturer in India. Leading Supplier of UNS NO4400 Slip On Flanges All over the World. Monel 400 Slip On Flanges Distributor and Exporter with Best Price and Discount

ASTM B564 Monel 400 Slip On Flanges Importers, Stockholder, Suppliers, Distributor and Exporter in India. Delivering High Quality ASME SB Alloy 400 Slip On Flanges on Time. Fast Delivery Guaranteed for every size UNS NO4400 Slip On Flanges, ASTM B564 Monel Slip On 400 Flanges, Largest range of Monel 400 Slip On Flanges, suppliers in India.

- What is Monel 400 Slip On Flanges

- ASTM B564 Monel 400 Flanges Specification

- Monel 400 Slip On Flanges Range and Offer

- ASTM A564 Monel 400 Slip On Flanges Chemical Compostion

- ASTM A564 Monel 400 Slip On Flanges Mechanical & Physical Properties, Yield Strength, Tensile, Elongation

- ASTM B564 Monel 400 Slip On Flanges Packing and Shipping

- ASTM B564 Monel 400 Slip On Flangese Application Industries

- ASTM B564 Monel 400 Slip On Flanges Special Offers and Discount

- ASTM B564 Monel 400 Slip On Flanges Exported and Supply Countries

What is Monel 400 Slip On Flanges?

Monel 400 Slip On Flanges is a nickel-copper alloy (about 67% Ni – 23% Cu) that is resistant to sea water and steam at high temperatures as well as to salt and caustic solutions. Alloy 400 is a solid solution alloy that can only be hardened by cold working. This nickel alloy exhibits characteristics like good corrosion resistance, good weldability and high strength. A low corrosion rate in rapidly flowing brackish or seawater combined with excellent resistance to stress-corrosion cracking in most freshwaters, and its resistance to a variety of corrosive conditions led to its wide use in marine applications and other non-oxidizing chloride solutions. This nickel alloy is particularly resistant to hydrochloric and hydrofluoric acids when they are de-aerated. As would be expected from its high copper content, alloy 400 is rapidly attacked by nitric acid and ammonia systems.

Monel 400 has great mechanical properties at subzero temperatures, can be used in temperatures up to 1000° F, and its melting point is 2370-2460° F. However, Alloy 400 is low in strength in the annealed condition so, a variety of tempers may be used to increase the strength.

Slip On Flanges manufactured with an inside diameter that is slightly bigger than the pipe's outside diameter. These attachments are connected to the pipe via fillet weld at the top and bottom of the flange. Slip on pipe Flanges are typically provided with a raised or flat face.

The calculated strength from a Slip On flange under internal pressure is of the order of two-thirds that of Welding Neck flanges, and their life under fatigue is about one-third that of the latter.

The connection with the pipe is done with 2 fillet welds, as well at the outside as also at the inside of the flange.

Prosaic Steel and Alloy Supply Monel 400 Slip On Flanges in All Sizes

ASTM B564 UNS NO4000 Forged Slip On Flanges Specification?

Standard Specification for Nickel Alloy Forgings This specification covers nickel alloy forgings. These alloys are classified into different grades according to their chemical composition. A chemical analysis shall be employed on each alloy in order to determine its chemical composition. Grain size and mechanical properties like tensile strength, yield strength, and elongation shall be measured. A tension test and nondestructive ultrasonic test shall be done on each specimen.

ASTM B564 UNS NO4000 Forged Slip On Flanges Range

| ASTM B564 Flanges Specification | ASTM B564 / ASME SB564 |

| ASTM B564 Pipe Grades | ASME SB564 / ASTM B564 Grades Monel, Inconel, Incoloy, Hasteloy Alloy 600, Alloy 601, Alloy 625, Alloy 800, Alloy 800HT, Alloy 825, Alloy C22, Alloy C-276,Alloy 20 |

| ASTM B564 Flanges Type | Forged and Rolled Flanges |

| ASTM B564 Flanges Outer Diameter Size | 1/2" NB To 48" NB (Nominal Bore Size) |

| ASTM B564 Flange Pressure Class | Class: 150#, 300#, 600#, 900#, 1500#, 2500#, PN6 TO PN100 |

| ASTM B564 Types | Weld Neck Flanges – WNRF, Socket Weld Flanges – SWRF, Slip On Raise Face Flange – SORF, Lap Joint Raise Face Flange – BLRF, Lap Joint Flange, Screwed (Threaded) Flange, Long Weld Neck Flange, Reducing Flange, Spectacle Lap Joint Flange, Ring Joint Flange, Large Die Ring Flange, Orifice Flange, Girth Flange etc. |

| ASTM B564 Flanges Delivery Conditions | As Rolled, Normalizing Rolled, Thermomechanical Rolled / Formed, Normalizing Formed, Normalized and Tempered / Quenched and Tempered - BR / N / Q /T, Machined |

| ASTM B564 Flanges Dimension Standard | Standard - ANSI - ANSI B16.5, ANSI B16.47, MSS SP44, ANSI B16.36, and ANSI B16.48 |

| ASTM B564 Flanges Other Testing | NACE MR0175, NACE TM0177, NACE TM0284, CHARPY V-NOTCH TEST, RADIOGRAPHIC EXAMINATION, XRAY, ULTRASONIC EXAMINATION, LIQUID PENETRANT, MAGNETIC PARTICLE, HIC TEST, SSC TEST, SWC, H2 SERVICE, IBR, PWHT etc. |

| ASTM B564 Flanges Value Added Services | Draw / Expansion / Machining / Sand Blasting / Shot Blasting / Galavanizing / Heat Treatment |

| ASTM B564 Flanges Packaging | Loose / Bundle / Wooden Pallet / Wooden Box / Plastic Cloth Wraps / Plastic End Caps / Beveled Protector |

| ASTM B564 Flanges Shipment & Transportation | By Road - Truck / Train, By Sea - Break-bulk Conventional Vessel / FCL (Full Container Load) / LCL (Less Container Load) / 20 Feet Container / 40 Feet Container / 45 Feet Container / High Cube Container / Open Top Container, By Air - Freighter Civil Passenger and Cargo Planes |

| ASTM B564 Flanges Material Test Certificate | Manufacturer Test Certificate As Per EN10204 3.1, 3.2 / Laboratory Test Certificate From NABL Approved Lab. / Under Third Party Inspection Agency Like SGS, TUV, DNV, LLOYDS, ABS ETC |

ASTM B564 Monel 400 Slip On Flanges Chemical Composition

| Element | Content (%) |

|---|---|

| Nickel, Ni | Remainder |

| Copper, Cu | 28-34 |

| Iron, Fe | 2.5 max |

| Manganese, Mn | 2 max |

| Silicon, Si | 0.5 max |

| Carbon, C | 0.3 max |

| Sulphur, S | 0.024 |

ASTM B564 Monel 400 Slip On Flanges Mechnical and Physical Properties

The following table discusses the physical properties of MONEL 400 alloy.

| Properties | Metric | Imperial |

|---|---|---|

| Density | 8.8 gm/cm3 | 0.318 lb/in3 |

The mechanical properties of MONEL 400 alloy are tabulated below.

| Properties | Metric | Imperial |

|---|---|---|

| Tensile strength(annealed) | 517-620 MPa | 75-90 ksi |

| Yield strength | 172-345 MPa | 25-50 ksi |

| Modulus of elasticity | 179 GPa | 26000 ksi |

| Poisson’s ratio | 0.32 | 0.32 |

| Standard | Monel 400 |

| UNS | N04400 |

| WERKSTOFF NR. | 2.4360 |

| AFNOR | NU-30M |

| JIS | NW 4400 |

| GOST | МНЖМц 28-2,5-1,5 |

| BS | NA 13 |

| EN | NiCu30Fe |

| MACHINING DATA | |

|---|---|

| Carbide tools are suggested for rates better than 50% of Type 304. |

|

| Machining Type | Suggested starting rates are: |

| Single Point turning : | Roughing - 0.15" depth, 0.015"/rev feed -175 SFM Finishing - 0.025" depth, 0.007"/rev feed - 200 SFM |

| Drilling : | 1/4" Dia hole - 0.004"/rev feed - 60 SFM 1/2" Dia hole - 0.007"/rev feed - 60 SFM 3/4" Dia hole - 0.010"/rev feed - 60 SFM |

| Reaming : | Feed - same as drilling - 100 SFM |

| Side and Slot Milling : | Roughing - 0.25" depth - 0.007"/tooth feed - 125SFM Finishing - 0.050" depth - 0.009"/tooth feed - 140SFM |

| These rates are for carbide tools, Type C-2 for roughing, drilling and reaming. Type C-3 for finishing. |

|

MONEL® is a registered trademark of the INCO family of companies.

Monel 400 Slip On Flanges Packing and Shipping

Monel 400 Slip On Flanges in are Palletize with Shrink Wrap Plastic or Packed in Wooden Box.

Both ends of each crate will indicate the order no., heat no., dimensions, weight and bundles or as requested. We can also offer customized packaging for Slip On Flange as per customer's requirement.

Export packaging is geared towards the protection, handling and transport of Monel 400 Slip On Flanges by air or sea freight and, as such, shares many characteristics with export and transport packaging. Utmost care must also be taken to make overseas packaging suitable for long periods of storage. It is important for overseas packaging to be designed with ease of handling in mind, so as to ensure A671 Pipe is treated with the utmost care at all times.

Monel 400 Slip On Flanges Application

- Marine fixtures, pumps, valves and piping systems for sea water applications

- Chemical plant equipment

- Aerospace applications

- Musical instruments

- Heat exchangers

- High pressure applications

- Offshore applications

- Onshore applications

- Welded pressure vessels for the storage of cryogens

Monel 400 Slip On Flanges Export Countries

We exportMonel 400 Slip On Flanges to Saudi Arabia, Iran, Iraq, United Arab Emirates, Qatar, Bahrain, Oman, Kuwait, Turkey, Egypt, Yemen, Syria, israel, Jordan, Cyprus, Singapore, Malaysia, Indonesia, Thailand, Vietnam, South Korea, Japan, Sri Lanka, Maldives, Bangladesh, Mayanmar, Taiwan, Cambodia, Argentina, Bolivia, Brazil, Chile, Venezuela, Colombia, Ecuador, Guyana, Paraguay, Uruguay, United States Of America, Canada, Mexico, Panama, Costa Rica, Puerto Rica, Trinidad And Tobago, Jamaica, Bahamas, Denmark, Russia, Norway, Germany, France, Italy, United Kingdom, Spain, Ukraine, Netherland, Belgium, Greece, Czech Republic, Portugal, Hungary, Albania, Austria, Switzerland, Slovakia, Finland, Ireland, Croatia, Slovenia, Malta, Nigeria, Algeria, Angola, South Africa, Libya, Egypt, Sudan, Equatorial Guinea, The Republic Of Congo, Gabon, europe, Africa, Asia, North America, South America, Middle East, Far East.etc

Prosaic Steel and Alloys is a well known worldwide exporter of Monel 400 Slip On Flanges, Prosaic Steel and Alloys is committed to provide each and every customer with the highest standard of customer service. We deals in Monel 400 Slip On Flange in India & Overseas, offering a wide range of Monel 400 Lap Joint Flange

Prosaic Steel and Alloys is Leading Manufacturer, Distributor, Exporter, Stockholder and Supplier of Monel 400 Slip On Flange in United States of America (USA), Saudi Arabia, Iran, Iraq, United Arab Emirates UAE), Singapore, Malaysia, Indonesia

Monel 400 Slip On Flanges | ASTM B564 UNS NO4400 Slip On Flanges | Alloy 400 Slip On Flanges

we provided ASTM B564 Monel 400 Slip On Flanges. We Carry Complete Range from 1/2" NB to 48" NB Prosaic Steel and Alloys Monel 400 Slip On Flanges Pipes are known for its High Quality and Competitive Price.

Monel 400 Flanges | Alloy 400 Flanges