Adapters are an extremely important pipe fitting that extend or terminate pipe runs. They are used to connect dissimilar pipes. These fittings are somewhat similar to pipe couplings, with the difference that they connect pipe of different types, one of which is an IPS (Iron Pipe Size). Flex couplings sometime act like adapters. Pipe adapters may have either male or female IPS threads on one end and the opposite gender on the other end, which needs to be welded or soldered onto a smaller pipe. Adapters are used in a myriad of applications but they are typically used to connect different pipes to fixtures.

Adapters are an extremely important pipe fitting that extend or terminate pipe runs. They are used to connect dissimilar pipes. These fittings are somewhat similar to pipe couplings, with the difference that they connect pipe of different types, one of which is an IPS (Iron Pipe Size). Flex couplings sometime act like adapters. Pipe adapters may have either male or female IPS threads on one end and the opposite gender on the other end, which needs to be welded or soldered onto a smaller pipe. Adapters are used in a myriad of applications but they are typically used to connect different pipes to fixtures.

Materials used:

High quality and durable materials are used for making pipe adapters. Some of the common materials include:

- Steel

- Cast Iron

- Aluminum

- Copper

- Polymers

- Brass

- Bronze etc.

Types of Pipe Adapters:

Adapters are available in various types and while different types of adapters are required for different applications. While buying adapters for pipe, the buyer should always select the right type for right application. Some of the common types of pipe adapter are:

Locking Pipe Adapter: These are special pipe adapters that are used to attach 6 inches pipe to drain basin of any size, which requires a straight-line connection.

Offset Pipe Adapter: These pipe adapters are used to attach 8 to 10 inches single wall pipe to 9 inches, 12 inches or 18 inches pipes used for drain basins and/or low profile drains, which require an offset connection.

Male Pipe Adapter: Male pipe adapters are designed in such a way that they make minimum volume connection from the female Pipe fittings on pressure gaugesand regulators to dead volume internal fittings.

Female Pipe Adapter: These pipe adapters make a minimum volume connection from the male pipe fittings, which are usually found in gas distribution plumbing to dead volume internal fittings.

Straight Thread Adapters:

These adapters are also referred as O-ring boss fittings and they are joined on the back of the male half of the connector against a locking surface of the female port. These adapters usually have straight threads, which do not seal and offer resistance for service pressure. Straight threaded adapters are again divided into two categories:

- Adjustable: As the name suggests, these adapters are adjustable and include fittings like elbows and tees. Adjustable straight threaded adapters help the user to change the shape in the direction as required, before they are tightened for assembling.

- Non-adjustable: These fittings include plug or connector and they simply screw into a port and generally require no adjustment.

Steel adapters that can be used in many different fluid conveyance applications. The variety of different steel adapters includes (but not exclusive to):

- ors

- sae o-ring

- split flange

- sae 45 degree flare

- sae 37 degree flare (jic)

- Pipe

- metric/bspp/bspt

Uses of Pipe adapters:

Some important uses of pipe adapters are as follows:

Adapters are applicable in all sanitary pipes.

They are food grade rated.

They are insulated.

They are plated.

They provide high purity and excellent chemical resistance.

Leak-free designs in adapters can withstand high-pressure.

Adapters are ideal for high-vibration or side-load stressed applications.

They offer better flow rates.

They offer fewer potential leak points, thereby providing a seamless and convenient transition from piping to tubing systems.

In some cases, adapters eliminate the need for welded or threaded connections, which in turn save time and cost.

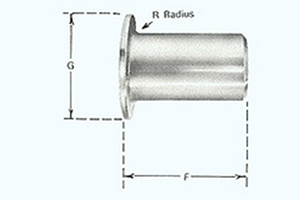

Stub Ends are fittings used in place of welded flanges where rotating back up flanges are desired. They are also called Lap Joints and Vanstone Flared Laps. A rotating back up flange seats itself against the back surface of the Stub End. When bolts are added, the clamping action of the bolts presses the rotating back up flange against the back of the Stub End. The gasket surface of the Stub End then presses against a gasket and another gasket surface providing joints like standard flange joints. The seal is made by the gasket surface of the stub end alone, the flange only provides the clamping pressure on the joint.

Stub Ends are fittings used in place of welded flanges where rotating back up flanges are desired. They are also called Lap Joints and Vanstone Flared Laps. A rotating back up flange seats itself against the back surface of the Stub End. When bolts are added, the clamping action of the bolts presses the rotating back up flange against the back of the Stub End. The gasket surface of the Stub End then presses against a gasket and another gasket surface providing joints like standard flange joints. The seal is made by the gasket surface of the stub end alone, the flange only provides the clamping pressure on the joint.

Our high quality stub ends (Butt weld fittings) are tested and verified for durability, accuracy and precision. The stub ends are manufactured in all standard dimensions. The stub ends are provided with a standard weld bevel and can be available in squared, flanged, victaulic and threaded ends. We offer stub ends at highly competitive prices.

Prosaic Steel & Alloys manufactures a wide range of stub ends (pipefitting) made of materials - exotic metals, nickel, cupro-nickel, Stainless Steel etc., of various grades. Prosaic Steel & Alloys manufactures & supplies high quality stub ends (pipe fittings) that can be used for various applications. Our stub ends are tested and verified for durability, accuracy and precision.

Prosaic Steel & Alloys manufactures seamless stub ends of long & short radius to MSS and ANSI B 16.9 standard from Schedules 10 to 160.

Prosaic Steel & Alloys designs & manufactures subtends (pipe fitting) of special type made according to drawing on request.

Material: A234-WPB A234-WP12 A234-WP11 A234-WP5 A403-WP304 A403-WP304L A403-WP316. A403-WP316L A420-WPL6, 316L, 304L, 321, 321H.

Size: 1/2" - 24"

Types: Type A, Type B, Type C, Type D

Manufacturing standard: ASME/ANSI B16.9, JIS, DIN, EN, API 5L, etc.

Surface treatment: Shot blasted, rust-proof black oil

| INCHES | METRIC | ||||||||||||

| N.B | O.D. At Bevel | F | Rad. Of Fillet R | Dia of Lap G | O.D. Of Barrel | N.B. | O.D. At Bevel | F | Rad. Of Fillet R | Dia of Lap G | O.D. Of Barrel | ||

| Max. | Min. | Max. | Min. | ||||||||||

| 1 - 2 |

0.84 | 3 | 1 - 8 |

1 3/8 | 0.9 | 0.81 | 15 | 21.34 | 76.2 | 3.18 | 34.93 | 22.76 | 20.55 |

| 3 - 4 |

1.05 | 3 | 1 - 8 |

1 11/16 | 1.11 | 1.02 | 20 | 26.67 | 76.2 | 3.18 | 42.86 | 28.09 | 25.88 |

| 1 | 1.32 | 4 | 1 - 8 |

2 | 1.38 | 1.28 | 25 | 33.4 | 101.6 | 3.18 | 50.8 | 34.95 | 32.61 |

| 1-1/4 | 1.66 | 4 | 3 - 16 |

2-1/2 | 1.72 | 1.63 | 32 | 42.16 | 101.6 | 4.76 | 63.5 | 43.59 | 41.38 |

| 1 1/2 | 1.9 | 4 | 1 - 4 |

2 7/8 | 1.97 | 1.87 | 40 | 48.26 | 101.6 | 6.35 | 73.03 | 49.94 | 47.47 |

| 2 | 2.38 | 6 | 5 - 16 |

3 5/8 | 2.46 | 2.34 | 50 | 60.33 | 152.4 | 7.94 | 92.08 | 62.38 | 59.54 |

| 2-1/2 | 2.88 | 6 | 5 - 16 |

4 1/8 | 2.97 | 2.84 | 65 | 73.03 | 152.4 | 7.94 | 104.78 | 75.34 | 72.24 |

| 3 | 3.5 | 6 | 3 - 8 |

5 | 3.6 | 3.47 | 80 | 88.9 | 152.4 | 9.53 | 127 | 91.34 | 88.11 |

| 3 1/2 | 4 | 6 | 3 - 8 |

5 1/2 | 4.1 | 3.97 | 90 | 101.6 | 152.4 | 9.53 | 139.7 | 104.04 | 100.81 |

| 4 | 4.5 | 6 | 7 - 16 |

6 3/16 | 4.59 | 4.47 | 100 | 114.3 | 152.4 | 11.11 | 157.16 | 116.66 | 113.51 |

| 5 | 5.56 | 8 | 7 - 16 |

7 5/16 | 5.68 | 5.53 | 125 | 141.3 | 203.2 | 11.11 | 185.74 | 144.35 | 140.51 |

| 6 | 6.63 | 8 | 1 - 2 |

8 1/2 | 6.74 | 6.59 | 150 | 168.28 | 203.2 | 12.7 | 215.9 | 171.27 | 167.49 |

| 8 | 8.63 | 8 | 1 - 2 |

10 5/8 | 8.74 | 8.59 | 200 | 219.08 | 203.2 | 12.7 | 269.88 | 222.07 | 218.29 |

| 10 | 10.75 | 10 | 1 - 2 |

12 3/4 | 10.91 | 10.72 | 250 | 273.05 | 254 | 12.7 | 323.85 | 277.19 | 272.26 |

| 12 | 12.75 | 10 | 1 - 2 |

15 | 12.91 | 12.72 | 300 | 323.85 | 254 | 12.7 | 381 | 327.99 | 323.06 |

| 14 | 14 | 12 | 1 - 2 |

16 1/4 | 14.17 | 13.97 | 350 | 355.6 | 304.8 | 12.7 | 412.75 | 359.92 | 354.81 |

| 16 | 16 | 12 | 1 - 2 |

18 1/2 | 16.18 | 15.97 | 400 | 406.4 | 304.8 | 12.7 | 469.9 | 410.97 | 405.61 |

| 18 | 18 | 12 | 1 - 2 |

21 | 18.19 | 17.97 | 450 | 457.2 | 304.8 | 12.7 | 533.4 | 462.03 | 456.41 |

| 20 | 20 | 12 | 1 - 2 |

23 | 20.24 | 19.97 | 500 | 508 | 304.8 | 12.7 | 584.2 | 514.1 | 507.21 |

| 22 | 22 | 12 | 1 - 2 |

25 1/4 | 22.24 | 21.97 | 550 | 558.8 | 304.8 | 12.7 | 641.35 | 564.9 | 558.01 |

| 24 | 24 | 12 | 1 - 2 |

27 1/4 | 24.24 | 23.97 | 600 | 609.6 | 304.8 | 12.7 | 692.15 | 615.7 | 608.81 |