Understanding API 5L X52 PSL1 Carbon Steel Seamless Pipes

The American Petroleum Institute specification API 5 X52 PSL1 Pipe covers seamless and welded steel line pipe. This is steel pipe for pipeline transportation systems in the petroleum and natural gas industries. API 5L is suitable for conveying gas, water, and oil.

Prosaic Steel and Alloys India Manufacturer & fabricator, Importer, Stockholder, Exporter of API 5L X52 PSL 1 Pipe, premier suppliers of bulk API 5L X52 PSL 1 Pipe stock worldwide. Fast delivery guaranteed for every size stainless steel API 5L X52 PSL 1 Pipe, carbon steel API 5L X52 PSL 1 Pipe & alloy steel pipe, largest range of API 5L X52 PSL 1 Pipe suppliers in India.

The American Petroleum Institute Pipe Specification

API 5L covers seamless and welded steel line pipe. This is

Steel Pipe for pipeline transportation systems in the petroleum and natural gas industries. API 5L is suitable for conveying gas, water, and oil. Size range is limited only by manufacturer’s capabilities.

Specifications for API 5L adhere to the International Organization for Standardization isO 3183, which standardizes pipeline transportation systems within the materials, equipment and offshore structures for petroleum, petrochemical, and natural gas industries. The technical committee authoring the standards recognized that there are two basic Product Pipe Specification Levels (PSL) of technical requirements and therefore developed PSL 1 and PSL 2. PSL 1 is a standard quality for line pipe where PSL 2 contains additional chemical, mechanical properties, and testing requirements.

Prosaic Steel Supply stocks a full range of API 5L X52 PSL-1 & PSL-2 line pipe in seamless.

We can help supply all of the Carbon Steel API 5L Gr. X52 Seamless Pipe or linepipe supplies that your company needs for use in the oil or natural gas industries. API 5L Line Pipe Specification for these pipes regulate usage for standard Grade A and Grade B pipes, with Grade X indicating stronger variants for drilling, production and transport requirements for offshore, arctic, deep well or harsher environments. Longitudinally welded Steel Pipe / Carbon Steel API 5L Gr. X52 Seamless Pipe are used in onshore and offshore oil and gas pipelines requiring critical service, high performance and tight tolerances

Understanding API 5L X52 PSL1 Carbon Steel Seamless Pipes

API 5L X52 PSL1 carbon steel seamless and Alloy Steel pipes are a popular choice for the transportation of oil, gas, and water in pipeline systems. These pipes meet the American Petroleum Institute (API) Pipe Specification and are designed for use in high-pressure, high-temperature environments. They offer excellent strength, toughness, and durability, making them suitable for a wide range of industries, including petrochemical, oil & gas, and construction.

Key Features and Benefits

Do you know API 5L X52 PSL1 Seamless Pipe offer several advantages, making them a popular metal product in overall product grade because they have many advantages every steel industry makes that product and every trader can easily find a product in the local marketplace but some companies have their own steel production house for manufacturing like Savoy Piping Inc, Prosaic Steel we explain below some key features of API 5L X52 PSL1 Seamless Pipe such as High Strength, Durability, Cost-Efficient

Common Applications in Various Industries

API 5L X52 PSL1 Carbon Steel Seamless Pipes are widely used in construction and other structural applications Many Industries use Stainless steel and Alloy Steel and other materials for their production of API 5L X52 PSL1 Seamless Pipe and its use in Major production houses such as Oil & Gas Transportation, Petrochemical Industry, Water Supply, Construction there are some essential points are explained below

- Oil & Gas Transportation

- Petrochemical Industry

- Water Supply

- Construction

The API 5L X52 PSL1 Seamless Pipe and Steel Plate is widely used in Oil & Gas Transportation for log distance and water oli and chemical transportations but after periods of time we have to change or replace our pipeline for their maintenance if we do not replace or change particular pipes so we face blockage in the pipeline and Petrochemical Industry Utilized in chemical processing plants where durability and resistance to pressure are critical and Suitable for high-pressure water pipelines in water distribution systems. Also, API 5L X52 PSL1 is Used in structural applications, particularly where high-strength materials are required.

Carbon Steel is used in the most critical engineering applications and also in certain applications in the automotive sector. In addition, some of the value-added Carbon Steel and

Alloy Steel products include steel for LPG cylinders, API grade, corrosion-resistant steel, critical structural application steel, boiler quality, auto grades, precision tubes and medium/high carbon grades, among others.

Pipe Specification for line pipe API SPEC 5L (-09)

specifies the requirements for the manufacture of two product specification levels (PSL1 and PSL2) of Seamless and welded Steel Pipe for use in pipeline transportation systems in the petroleum and natural gas industries and Grades covered by this Pipe Specification are A25 ,A ,B (and the following "X" Grades) X42, X46, X52, X56, X60, X65, X70, X80 The two digit number following the "X" indicates the Minimum Yield Strength (in 000's psi) of pipe produced to this grade.

Chemical Composition of API 5L X52 PSL1 Pipes with t ≤ 0.984”

| Alloy Steel Steel Grade | Mass fraction, % based on heat and product analyses a,g | ||||||

|---|---|---|---|---|---|---|---|

| C | Mn | P | S | V | Nb | Ti | |

| max b | max b | max | max | max | max | max | |

| X52 | 0.28 | 1.4 | 0.3 | 0.3 | d | d | d |

| X52 | 0.26 | 1.4 | 0.3 | 0.3 | d | d | d |

| a. Cu ≤ = 0.50% Ni; ≤ 0.50%; Cr ≤ 0.50%; and Mo ≤ 0.15%, b. For each reduction of 0.01% below the specified maximum concentration for carbon, an increase of 0.05% above the specified maximum concentration for Mn is permissible, up to a maximum of 1.65% for grades ≥ L245 or B, but ≤ L360 or X52; up to a maximum of 1.75% for grades > L360 or X52, but < L485 or X70; and up to a maximum of 2.00% for grade L485 or X70., c. Unless otherwise agreed NB + V ≤ 0.06%, d. Nb + V + TI ≤ 0.15%, e. Unless otherwise agreed., f. Unless otherwise agreed, NB + V = Ti ≤ 0.15%, g. No deliberate addition of B is permitted and the residual B ≤ 0.001% |

|||||||

Mechanical Properties Tensile and Yield of API 5L X52 PSL1 Pipe

| Pipe Grade | Tensile Properties – Pipe Body of SMLS and Welded Pipes PSL 1 | Seam of Welded Pipe | ||

|---|---|---|---|---|

| Yield Strength a | Tensile Strength a | Elongation | Tensile Strength b | |

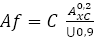

| Rt0,5 PSI Min | Rm PSI Min | (in 2in Af % min) | Rm PSI Min | |

| X52 | 52,200 | 66,700 | c | 66,700 |

| a. For intermediate grade, the difference between the specified minimum tensile strength and the specified minimum yield for the pipe body shall be as given for the next higher grade. | ||||

| b. For the intermediate grades, the specified minimum tensile strength for the weld seam shall be the same as determined for the body using foot note a. | ||||

| c. The specified minimum elongation, Af, expressed in percent and rounded to the nearest percent, shall be determined using the following equation: | ||||

|

||||

| Where C is 1 940 for calculation using Si units and 625 000 for calculation using USC units | ||||

| Axc is the applicable tensile test piece cross-sectional area, expressed in square millimeters (square inches) , as follows | ||||

| – For circular cross-section test pieces, 130mm2 (0.20 in2) for 12.7 mm (0.500 in) and 8.9 mm (.350 in) diameter test pieces; and 65 mm2 (0.10 in2) for 6.4 mm (0.250in) diameter test pieces. | ||||

| – For full-section test pieces, the lesser of a) 485 mm2 (0.75 in2) and b) the cross-sectional area of the test piece, derived using the specified outside diameter and the specified wall thickness of the Steel Plate and pipe, rounded to the nearest 10 mm2 (0.10in2) | ||||

| – For strip test pieces, the lesser of a) 485 mm2 (0.75 in2) and b) the cross-sectional area of the test piece, derived using the specified width of the test piece and the specified wall thickness of the pipe and Steel Plate rounded to the nearest 10 mm2 (0.10in2) | ||||

| U is the specified minimum tensile strength, expressed in megapascals (pounds per square inch) | ||||

• 0.50% maximum for copper, 0.50% maximum for nickel, 0.50% maximum for chromium, and 0.15% maximum for molybdenum.

• For each reduction of 0.01% below the specified maximum concetration for carbon, an increase of 0.05% above the specified maximum concentration for manganese is permissible, up to a maximum of 1.65%

• Unless otherwise agreed, the sum of the niobium and vanadium contents shall be ≤0.06%.

• The sum of the niobium ,vanadium and titanium concentratons shall be ≤0.06%.

• Unless otheriwse agreed.

• Unless otherwise agreed, the sum of niobium, vanadium and titanium concentrations shall be ≤ 0.15%

API 5L X52 PSL1 Pipe Grades and acceptable Delivery Conditions:

| PSL | Delivery Condition | Pipe and Steel Plate grade |

|---|---|---|

| PSL1 | As-rolled, normalized, normalizing formed | A |

| As-rolled, normalizing rolled, thermomechanical rolled, thermo-mechanical formed, normalizing formed, normalized, normalized and tempered or if agreed Q&T SMLS only | B | |

| As-rolled, normalizing rolled, thermomechanical rolled, thermo-mechanical formed, normalizing formed, normalized, normalized and tempered | X42, X46, X52, X56, X60, X65, X70 | |

| PSL 2 | As-rolled | BR, X42R |

| Normalizing rolled, normalizing formed, normalized or normalized and tempered | BN, X42N, X46N, X52N, X56N, X60N | |

| Quenched and tempered | BQ, X42Q, X46Q, X56Q, X60Q, X65Q, X70Q, X80Q, X90Q, X100Q | |

| Thermomechanical rolled or thermomechanical formed | BM, X42M, X46M, X56M, X60M, X65M, X70M, X80M | |

| Thermomechanical rolled | X90M, X100M, X120M | |

| The suffice (R, N, Q or M) for PSL2 grades, belongs to the steel and Alloy Steel grade |

API 5L X52 PSL1 Ordering Information

The purchase order shall include the quantity, PSL level, type or Grade, reference to API5L, outside diameter, wall thickness, length and any applicable annexes or additional requirements related to chemical composition, mechanical properties, heat treatment, additional testing, manufacturing process, surface coatings or end finish.

API 5L X52 PSL1 Pipe Starting Material

Ingots, blooms, billets, coils or plates used for the manufacture of pipe and Steel Plate shall be made by the following processes, basic oxygen, electric furnace or open hearth in combination with a ladle refining process. For PSL2, the steel Alloy Steel shall be killed and melted according to a fine grain practice. Coil or plate used for PSL2 pipe shall not contain any repair welds.

API 5L X52 PSL1 Pipe Process of Manufacturing

| Type of Pipe | PSL 1 | PSL 2 | |||

|---|---|---|---|---|---|

| Grade A | Grade B | X42 to X70 | B to X80 | X80 to X100 | |

| SMLS | ✔ | ✔ | ✔ | ✔ | ✔ |

| LFW | ✔ | ✔ | ✔ | ||

| HFW | ✔ | ✔ | ✔ | ✔ | |

| LW | ✔ | ||||

| SAWL | ✔ | ✔ | ✔ | ✔ | ✔ |

| SAWH | ✔ | ✔ | ✔ | ✔ | ✔ |

| SMLS – Seamless, without weld LFW – Low frequency welded pipe, <70 kHz HFW – High frequency welded pipe, >70 kHz SAWL – Submerge-arc welding longitudinal welded SAWH - Submerge-arc welding helical welded |

|||||

API 5L X52 PSL1 Dimenenion Tolerances Outside Diameter, Out of roundness and wall thickness

| Specified Outside Diameter D (in) | Diameter Tolerance, inches d | Out-of-Roundness Tolerance in | ||||

|---|---|---|---|---|---|---|

| Pipe except the end a | Pipe end a,b,c | Pipe except the End a | Pipe End a,b,c | |||

| SMLS Pipe | Welded Pipe | SMLS Pipe | Welded Pipe | |||

| < 2.375 | -0.031 to + 0.016 | – 0.031 to + 0.016 | 0.048 | 0.036 | ||

| ≥2.375 to 6.625 | 0.020D for | 0.015D for | ||||

| +/- 0.0075D | – 0.016 to + 0.063 | D/t≤75 | D/t≤75 | |||

| By agreement for | By agreement for | |||||

| D/t≤75 | D/t≤75 | |||||

| >6.625 to 24.000 | +/- 0.0075D | +/- 0.0075D, but max of 0.125 | +/- 0.005D, but max of 0.063 | 0.020D | 0.015D | |

| >24 to 56 | +/- 0.01D | +/- 0.005D but max of 0.160 | +/- 0.079 | +/- 0.063 | 0.015D for but max of 0.060 | 0.01D for but max of 0.500 |

| For | For | |||||

| D/t≤75 | D/t≤75 | |||||

| By agreement | By agreement | |||||

| for | for | |||||

| D/t≤75 | D/t≤75 | |||||

| >56 | As agreed | |||||

| a. The pipe and Steel Plate end includes a length of 4 in ate each of the pipe extremities | ||||||

| b. For SMLS pipe and Steel Plate the tolerance apply for t≤0.984in and the tolerances for the thicker pipe shall be as agreed | ||||||

| c. For expanded pipe with D≥8.625in and for non-expanded pipe, the diameter tolerance and the out-of-roundness tolerance may be determined using the calculated inside diameter or measured inside diameter rather than the specified OD. | ||||||

| d. For determining compliance to diameter tolerance, the pipe Steel Plate diameter is defined as the circumference of the pipe in any circumferential plane divide by Pi. | ||||||

| Wall thickness | Tolerances a |

|---|---|

| t inches | inches |

| SMLS pipe b | |

| ≤ 0.157 | -1.2 |

| >0.157 to < 0.948 | + 0.150t / – 0.125t |

| ≥ 0.984 | + 0.146 or + 0.1t, whichever is the greater |

| – 0.120 or – 0.1t, whichever is the greater | |

| Welded pipe c,d | |

| ≤ 0.197 | +/- 0.020 |

| > 0.197 to < 0.591 | +/- 0.1t |

| ≥ 0.591 | +/- 0.060 |

| a. If the purchase order specifies a minus tolerance for wall thickness smaller than the applicable value given in this table, the plus tolerance for wall thickness shall be increased by an amount sufficient to maintain the applicable tolerance range. | |

| b. For pipe and Steel Plate with D≥ 14.000 in and t≥0.984in, the wall thickness tolerance locally may exceed the plus tolerance for wall thickness by an additional 0.05t provided that the plus tolerance for mass is not exceeded. | |

| c. The plus tolerance for wall thickens does not apply to the weld area | |

| d. See the full API5L spec for full details | |

API 5L X52 PSL1 Hydrostatic Test

Pipe to withstand a hydrostatic test without leakage through the weld seam or the pipe and Steel Plate body. Jointers need not be hydrostatic tested provide the pipe sections used were successfully tested.

API 5L X52 PSL1 Pipe Bend Test

No cracks shall occur in any portion of the test piece and not opening of the weld shall occur.

API 5L X52 PSL1 Pipe Acceptance criteria for flattening test shall be

- EW pipes D 12.750 in

- ≥ X60 with T≥0.500in, there shall be no opening of the weld before the distance between the plates is less than 66% of the original outside diameter. For all grades and wall, 50%.

- For pipe with a D/t 10, there shall be no opening of the weld before the distance between the plates is less than 30% of the original outside diameter.

- For other sizes refer to the full API5L specification

CVN impact test for PSL2

Many PSL2 pipe sizes and grades require CVN. Seamless pipe Steel Plate is to be tested in the body. Welded pipe is to be tested in the Body, Pipe Weld and heat affected zone (HAZ). Refer to the full API5L Pipe Specification for the chart of sizes and grades and required absorbed energy values.

API 5L Pipes and Steel Plate Material Grades

| High Temperature Seamless Pipe | ASTM A106 Gr. B/C, API 5L Gr. B, ASTM A53 Gr. B |

| Heat Exchanger Seamless Tube | ASTM A179 |

| Low Temperature Seamless Pipe | ASTM A333 Gr. 3/6 |

| Low Temperature Seamless Tube | ASTM A334 Gr. 6 |

| High Yield Seamless Pipe | API 5L Gr. X42/X46/X52/X56/X60/X65/X70/X80 PSL-1/PSL-2 |

| High Yield Seamless Pipe | ISO 3183 Gr. L245, L290, L320, L360, L390, L415, L450, L485 |

| Atmospheric & Low Temp EFW Pipes | ASTM A671 Gr. CC60/CC65/CC70 |

| High Pressure & Moderate Temp EFW Pipes | ASTM A672 Gr. B60/B65/B70/C55/C60/C65/C70 |

| High Yield ERW/SAW Pipe | API 5L Gr. X42/X46/X52/X56/X60/X65/X70/X80 PSL-1/PSL-2 |

| High Yield ERW/SAW Pipe | ISO 3183 Gr. L245, L290, L320, L360, L390, L415, L450, L485 |

API 5L Carbon Steel Seamless and Alloy Steel Pipes Types

API-5L X52 Line Pipe Types

Ranges by Product Pipe Specification Level: PSL1, PSL2, Sour Services

- API 5L X52 PSL1, for the pipes in common delivery condition of As Rolled.

- API 5L X52N/M/Q, for PSL2 pipe with delivery condition of N, M, and Q.

- API 5L X52NS/MS/QS, for PSL2 pipes with sour services.

- R: As rolled

- N: Normalizing rolled, Normalized formed, Normalized

- Q: Tempered and quenched

- M: Thermomechanical rolled or thermomechanical formed

- S: Sour Service

Seamless: Includes hot rolled seamless and cold drawn seamless.

ERW: Electric Resistance Welded, OD up to 24 inch.

DSAW/SAW: Double Sub-merged Arck Welding, substitute welding methods than ERW for larger diameter welded pipes.

LSAW: Longitudinal Sub-merged Arc Welding, also called JCOE pipe, OD up to 56 inch.

SSAW / HSAW: Spiral Sub-merged Arc Welding, or Helical SAW, OD up to 100 inch.

Inspection & Approval Certificates : EN10204 3.1 / DIN 50049 3.1 / isO 10474 3.1 Mill Test Certificate, NACE MR-0175 / isO 15156, NACE MR-01-03 / NACE MR-01-75 / isO 15156, CE Marked, European Pressure Equipment Directive PED-97/23/EC, AD-2000-W0, ASME Boiler & Pressure Vessel Code Sec.II Part A Ed. 2008, with 3.2 certificate duly Certified & Approved by LRS (Lloyd's Register), GL (Germanischer Lloyd), BV (Bureau Veritas), DNV (Det Norske Veritas), ABS (American Bureau of Shipping), SGS, TUV, RINA, IRS, NORSOK Approved Standard M-630,

API 5L X52 PSL1 Carbon Steel Seamless and Alloy SteelPipe Packing

API 5L X52 PSL1 Carbon Steel Seamless Pipe is sleeved into plastic bag individually, pieces wrapped with water-proof material, bundled with nylon rope. Clear labels are tagged on the outside of the package for easy identification of the quantity and product I.D. Great care is taken during operation and transportation. API 5L X52 PSL1

Carbon Steel Seamless Pipe and

Steel Plate packing will be according to international standard in bundles strapped by strips then into containers to avoid any damage.

Delivery: Within 10-25 days or asap if we have enough stock

Types of Packaging:

- - Bundles (hexagonal)

- - Wooden Boxes

- - Crates (steel/wooden)

- - Special crates for U-Bend tubes with each radius separated

- - Packaging for API 5L X52 PSL1 Carbon Steel Seamless Pipe as per customer's requirements

Special Features:

- - Each bundle covered with plastic for protection against extreme weather.

- - End of API 5L X52 PSL1 Carbon Steel Seamless Pipe protected by plastic caps.

- - Bundles strapped with plastic strips.

- - Each radius of U-Bend tube separated by a separator.

- - Packaging list (laminated) placed with box/crate.

API 5L X52 PSL1 Carbon Steel Seamless and Alloy Steel Pipe Export Country

We export API 5L X52 PSL1 Carbon Steel Seamless Pipe Saudi Arabia, Iran, Iraq, United Arab Emirates, Qatar, Bahrain, Oman, Kuwait, Turkey, Egypt, Yemen, Syria, israel, Jordan, Cyprus, Singapore, Malaysia, Indonesia, Thailand, Vietnam, South Korea, Japan, Sri Lanka, Maldives, Bangladesh, Mayanmar, Taiwan, Cambodia, Argentina, Bolivia, Brazil, Chile, Venezuela, Colombia, Ecuador, Guyana, Paraguay, Uruguay, United States of America, Canada, Mexico, Panama, Costa Rica, Puerto Rica, Trinidad And Tobago, Jamaica, Bahamas, Denmark, Russia, Norway, Germany, France, Italy, United Kingdom, Spain, Ukraine, Netherland, Belgium, Greece, Czech Republic, Portugal, Hungary, Albania, Austria, Switzerland, Slovakia, Finland, Ireland, Croatia, Slovenia, Malta, Nigeria, Algeria, Angola, South Africa, Libya, Egypt, Sudan, Equatorial Guinea, The Republic of Congo, Gabon, Europe, Africa, Asia, North America, South America, Middle East, Far East.etc.

Prosaic Steel and Alloys is a well known worldwide exporter of API 5L X52 PSL1 Carbon Steel Seamless Pipe, Prosaic Steel and Alloys is committed to provide each and every customer with the highest standard of customer service. We deals in API 5L X52 PSL1 Carbon Steel Seamless Pipe in India & Overseas, offering a wide range of

API 5L X52 PSL1 Carbon Steel Seamless Pipe.