Step-by-Step Installation Guide for DIN 2605 Part 1 Type 5 Elbow

Steel Buttwelding Pipe Fittings - Elbows and Bends for use at Full service Pressure DIN 2605 standard specifies the design and dimensions of seamless and welded steel elbows and bends rated for the same internal pressure as the pipes to which they are to be connected (cf. clause 6).

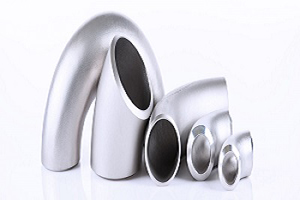

DIN 2605-1 Type 5 Elbow Manufacturer, Stockholder, Suppliers, Distributor and Exporter in India. Delivering High Quality DIN 2605 Type 5 Elbow on Time. Fast Delivery Guaranteed for every size DIn 2605-1 Elbow Largest range of DIN 2605-2 Type 45 Degree Elbow, 90 Degree Elbow and 180 Degree Elbow, suppliers based in India.

Understanding the DIN 2605 Part 1 Type 5 Elbow

DIN 2605-1 Type 5 Elbow are the results of work at national, European and/or international level. Anyone can submit a proposal for a new standard. Once accepted, the standards project is carried out according to set rules of procedure by the relevant DIN Standards Committee, the relevant Technical Committee of the European standards organization CEN (CENELEC for electrotechnical standards) or the relevant committee at the international standards organization isO (IEC for electrotechnical projects).

All stakeholders can participate in this work, including manufacturers, consumers, businesses, research institutes, public authorities and testing bodies. They send experts to represent their interests within DIN's working bodies, which are overseen by some 70 standards committees, each of which is responsible for a specific subject area. For work at European and international level, the DIN standards committees send experts to represent German interests within CEN and isO, respectively. DIN staff members coordinate the standardization process and are responsible for overall project management, ensuring the uniformity and consistency of the German standards collection.

DIN 2605-1 Type 5 Elbow Specification?

Steel Buttwelding Pipe Fittings - Pipe Elbows and Bends for use at Full service Pressure DIN 2605 standard specifies the design and dimensions of seamless and Weld Fittings steel Pipe Elbows and bends rated for the same internal pressure as the pipes to which they are to be connected (cf. clause 6). As the pressure rating of pipes is a function of their wall thickness, fittings have been classified according to wall thickness series (cf. table 1).

Preparing for Installation: Tools and Materials Needed

Ensure the IN 2605 Part 1 Elbow workspace is clean and free from obstacles. Prepare all necessary materials, including the DIN 2605 Type 5 elbow there are some essential Installation Tools and Materials Needed such as Wearing appropriate safety gear such as gloves and protective eyewear and Inspect the elbow and the pipes Do you know why inspection is important because it easy we find visible damage, cracks, or debris any products must be clean and free of obstructions.

- Wear appropriate safety gea

- Inspect the elbow and the pipes

Step-by-Step Installation Process

DIN 2605 Part 1 Type 5 Elbow refers to a pipe fitting that changes the direction of the flow in a piping system by 45°, 90°, or 180°. It's commonly used in industries such as oil & gas, petrochemicals, and water treatment. Prosaic Steel explains here some essential points of the Installation Process such as Preparing the Area and Materials, Measure and Cut the Pipes, Deburr the Pipe Ends, Fit the Elbow to the Pipe, Join the Elbow to the Pipes and final Inspection and Testing its a proper Process of Installation DIN 2605 Part 1 Type 5 Elbow

- Prepare the Area and Material

- Measure and Cut the Pipes

- Deburr the Pipe Ends

- Fit the Elbow to the Pipe

Measure and Cutting the Pipes is one important concept of the Installation Process Measure the length of the pipes that need to be connected to the elbow. Ensure you account for the depth of the pipe that will go into the elbow's socket and Cut the pipes to size using a pipe cutter or saw. Make sure the cuts are straight to allow for a proper fit otherwise, it is not useable for

Hydraulic Industrial workspace

Deburr the Pipe Ends Once the Pipe Elbows are cut, it's important to smoothen the ends Use a deburring tool to remove any sharp edges or burrs from the cut ends of the pipes Clean the pipe ends with a cloth to remove any debris or particles Adjust the angle relative to the pipe. Dry fit the angle to the Pipe Elbows before applying sealant or Weld Fittings. Make sure the

Pipe Elbows is properly positioned on the angle and the angle is correct. If necessary, check the flow direction to make sure the bracket is installed in the correct direction.

Maintenance Tips for Ensuring Longevity of Your Elbow Joint

Prosaic Steel & Alloys provides complete guidelines for Maintenance and Care for your DIN 2605 Part 1 Type 5 Elbow They have much experience in the maintenance of all grad Pipe Elbows tubes and fitting or plates during all sessions like winter and summer monsoons To maintain the appearance and properties of DIN 2605 Part 1 Type 5 Elbow, regular cleaning is recommended. Avoid the use of harsh chemicals or abrasives that may damage the surface.

DIN 2605-1 Type 5 Elbow Range

| DIN 2605 Elbow Specification | DIN 2605Part 1 and DIN 2605 Part 2. EN10253 Typ A and B, ASME B16.9, production according to customer specification. |

| DIN 2605 Elbow and 45 Deg Elbow Grades | EN / DIN()

|

| DIN 2605 Elbow Shapes | 45 deg Elbow / 90º ELBOW/ 180º ELBOW |

| DIN 2605 Elbow Outer Diameter & Wall Thickness Size | 1/2" NB To 32" NB (Nominal Bore Size) Wall Thickness: from 1 mm to 50 mm, depending on the outside diameter |

| DIN 2605 Elbow Make Process | SEAMLESS AND Weld Fittings in 2D, 3D, 5D, long radius, short radius - 2D, 3D, 5D, long radius, short radius |

| DIN 2605 Elbow Types | DIN 2605-1 Type 3, DIN 2605-1 TYPE 3, DIN 2605-1 TYPE 4, DIN 2605-1 TYPE 5, DIN 2605-2 Type 3, DIN 2605-2 TYPE 3, DIN 2605-2 TYPE 4, DIN 2605-2 TYPE 5 |

| DIN 2605 Elbow Delivery Conditions | As Rolled, Normalizing Rolled, Thermomechanical Rolled / Formed, Normalizing Formed, Normalized and Tempered / Quenched and Tempered - BR / N / Q /T, Machined |

| DIN 2605 Elbow Dimension Standard | Standard - ANSI - ANSI B16.5, ANSI B16.47, MSS SP44, ANSI B16.28, ANSI B16.36, and ANSI B16.48 |

| DIN 2605 Elbow Other Testing | NACE MR0175, NACE TM0177, NACE TM0284, CHARPY V-NOTCH TEST, RADIOGRAPHIC EXAMINATION, XRAY, ULTRASONIC EXAMINATION, LIQUID PENETRANT, MAGNETIC PARTICLE, HIC TEST, SSC TEST, SWC, H2 SERVICE, IBR, PWHT etc. |

| DIN 2605 Elbow Value Added Services | Draw / Expansion / Machining / Sand Blasting / Shot Blasting / Galavanizing / Heat Treatment |

| DIn 2605 Elbow and 45 Deg Elbow Packaging | Loose / Bundle / Wooden Pallet / Wooden Box / Plastic Cloth Wraps / Plastic End Caps / Beveled Protector |

| DIN 2605 Elbow Shipment & Transportation | By Road - Truck / Train, By Sea - Break-bulk Conventional Vessel / FCL (Full Container Load) / LCL (Less Container Load) / 20 Feet Container / 40 Feet Container / 45 Feet Container / High Cube Container / Open Top Container, By Air - Freighter Civil Passenger and Cargo Planes |

| DIN 2605 Elbow and 45 Deg Elbow Material Test Certificate | Manufacturer Test Certificate As Per EN10204 3.1, 3.2 / Laboratory Test Certificate From NABL Approved Lab. / Under Third Party Inspection Agency Like SGS, TUV, DNV, LLOYDS, ABS ETC |

DIN 2605-1 Type 5 Elbow and 45 Deg Elbow Available Grades

| EN / DIN | ASME / ASTM |

| P235GHTC1/2 (St 35.8 I/ III), P265GH, S355J2H, 16Mo3 (15Mo3), 10CrMo9-10 (10CrMo910), 13CrMo4-5 (13CrMo44), X11CrMo5, X11CrMo9-1, X20CrMOV11-1, X10CrMoVNb9-1, X10CrWMoVNb9-2, 7CrMoVTiB10-10, P215NL (TTST35N/V), 12Ni14 (10Ni14), P355N (StE355), P355NH (WStE355), P355NL1 (TStE355), P355NL2, L290NB (STE 290.7), L360NB (STE 360.7),1.4301, 1.4306, 1.4362(Lean Duplex), 1.4401, 1.4404, 1.4435, 1.4436, 1.4439, 1.4462(Duplex), 1.4466(Super Duplex), 1.4501, 1.4539, 1.4541, 1.4550, 1.4571 1.4841, 1.4878, 1.4876, 1.4952, 1.4835, 1.4877, 1.4910 | St 35.8 I + III, 15 Mo 3, 13 CrMo 4 4, 10 CrMo 9 10, TTSt 35 N, St 52.0, st WPA, WPB, WPC, WP1, WP5, WP9, WP11, WP12, WP22, WP32/27, WP91, WP92, WP304, WP304 H, WP304L, WP310, WP316, WP316L, WP316TI, WP321, WP347, WP347H, WPL 3, WPL6, X42, X52, WPHY52, WPHY60, S30815, S31000, S31050, S31500, S31726, S31803, S32760, N08904, Alloy 800H, DMV310N52.4 |

DIN 2605-1 Type 5 Elbow Types

DIN 2605-1 Type 5 Elbow Packing and Shipping

| 15 | 21,3 | R=17,5 | R=28 | R=42,5 | |

| b=28 | b=38 | b=53 | |||

| 2.0 | 0,03 | 0,04 | 0,07 | ||

| 2,3 | 0,03 | 0,05 | 0,07 | ||

| 2,6 | 0,04 | 0,05 | 0,08 | ||

| 2,9 | 0,04 | 0,06 | 0,09 | ||

| 3,2 | 0,05 | 0,07 | 0,10 | ||

| 3,6 | 0,05 | 0,08 | 0,12 | ||

| 20 | 26,9 | R=25 | R=29 | R=57,5 | |

| b=39 | b=43 | b=71 | |||

| 2.3 | 0,06 | 0,06 | 0,13 | ||

| 2,6 | 0,06 | 0,07 | 0,14 | ||

| 2,9 | 0,06 | 0,08 | 0,16 | ||

| 3,2 | 0,07 | 0,09 | 0,17 | ||

| 3,6 | 0,07 | 0,10 | 0,19 | ||

| 4,0 | 0,08 | 0,10 | 0,21 | ||

| 4,5 | 0,09 | 0,11 | 0,24 | ||

| 25 | 33,7 | R=25 | R=38 | R=72,5 | |

| b=42 | b=56 | b=90 | |||

| 2,6 | 0,10 | 0,12 | 0,23 | ||

| 2,9 | 0,11 | 0,13 | 0,25 | ||

| 3,2 | 0,12 | 0,15 | 0,28 | ||

| 3,6 | 0,13 | 0,16 | 0,31 | ||

| 4,0 | 0,14 | 0,18 | 0,34 | ||

| 4,5 | 0,14 | 0,20 | 0,37 | ||

| 5,0 | 0,15 | 0,21 | 0,41 | ||

| 32 | 38,0 | R=32,5 | R=45 | R=82 | |

| b=52 | b=64 | b=101 | |||

| 2,6 | 0,12 | 0,16 | 0,30 | ||

| 2,9 | 0,13 | 0,18 | 0,33 | ||

| 3,2 | 0,14 | 0,20 | 0,36 | ||

| 3,6 | 0,16 | 0,22 | 0,40 | ||

| 4,0 | 0,17 | 0,24 | 0,44 | ||

| 42,4 | R=32 | R=48 | R=92,5 | ||

| b=53 | b=69 | b=114 | |||

| 2,6 | 0,15 | 0,19 | 0,37 | ||

| 2,9 | 0,17 | 0,21 | 0,41 | ||

| 3,2 | 0,18 | 0,23 | 0,45 | ||

| 3,6 | 0,21 | 0,26 | 0,50 | ||

| 4,0 | 0,23 | 0,29 | 0,55 | ||

| 4,5 | 0,25 | 0,32 | 0,60 | ||

| 5,0 | 0,27 | 0,35 | 0,70 | ||

| 40 | 44,5 | R=40 | R=51 | R=97,5 | |

| b=62 | b=73 | b=130 | |||

| 2,6 | 0,17 | 0,22 | 0,41 | ||

| 2,9 | 0,19 | 0,24 | 0,46 | ||

| 3,2 | 0,21 | 0,26 | 0,50 | ||

| 3,6 | 0,23 | 0,29 | 0,56 | ||

| 4,0 | 0,25 | 0,32 | 0,61 | ||

| 48,3 | R=38 | R=57 | R=107,5 | ||

| b=62 | b=81 | b=132 | |||

| 2,6 | 0,20 | 0,26 | 0,50 | ||

| 2,9 | 0,22 | 0,29 | 0,55 | ||

| 3,2 | 0,24 | 0,32 | 0,60 | ||

| 3,6 | 0,27 | 0,36 | 0,67 | ||

| 4,0 | 0,29 | 0,39 | 0,74 | ||

| 4,5 | 0,33 | 0,44 | 0,82 | ||

| 5,0 | 0,37 | 0,48 | 0,90 | ||

| 50 | 57,0 | R=52,5 | R=72 | R=127,5 | |

| b=81 | b=100 | b=156 | |||

| 2,9 | 0,32 | 0,44 | 0,78 | ||

| 3,2 | 0,35 | 0,48 | 0,85 | ||

| 3,6 | 0,39 | 0,54 | 0,95 | ||

| 4,0 | 0,43 | 0,59 | 1,05 | ||

| 4,5 | 0,48 | 0,66 | 1,17 | ||

| 5,0 | 0,53 | 0,73 | 1,29 | ||

| 5,6 | 0,59 | 0,81 | 1,42 | ||

| 6,3 | 0,65 | 0,89 | 1,58 | ||

| 60,3 | R=51 | R=76 | R=135 | ||

| b=81 | b=106 | b=165 | |||

| 2,9 | 0,36 | 0,49 | 0,87 | ||

| 3,2 | 0,39 | 0,54 | 0,96 | ||

| 3,6 | 0,44 | 0,60 | 1,07 | ||

| 4,0 | 0,48 | 0,67 | 1,17 | ||

| 4,5 | 0,54 | 0,74 | 1,32 | ||

| 5,0 | 0,59 | 0,82 | 1,45 | ||

| 5,6 | 0,66 | 0,90 | 1,60 | ||

| 6,3 | 0,73 | 1,00 | 1,78 | ||

| 7,1 | 0,78 | 1,11 | 1,90 | ||

| 65 | 76,1 | R=63 | R=95 | R=175 | |

| b=102 | b=133 | b=213 | |||

| 2,9 | 0,58 | 0,78 | 1,44 | ||

| 3,2 | 0,64 | 0,86 | 1,58 | ||

| 3,6 | 0,71 | 0,96 | 1,77 | ||

| 4,0 | 0,78 | 1,06 | 1,96 | ||

| 4,5 | 0,88 | 1,19 | 2,19 | ||

| 5,0 | 0,97 | 1,31 | 2,41 | ||

| 5,6 | 1,07 | 1,46 | 2,68 | ||

| 6,3 | 1,19 | 1,62 | 2,98 | ||

| 7,1 | 1,33 | 1,81 | 3,32 | ||

| 8,0 | 1,48 | 2,01 | 3,70 | ||

| 80 | 88,9 | R=76 | R=114 | R=205 | |

| b=121 | b=159 | b=250 | |||

| 3,2 | 0,88 | 1,22 | 2,18 | ||

| 3,6 | 0,96 | 1,36 | 2,44 | ||

| 4,0 | 1,09 | 1,51 | 2,70 | ||

| 4,5 | 1,22 | 1,69 | 3,02 | ||

| 5,0 | 1,34 | 1,86 | 3,33 | ||

| 5,6 | 1,49 | 2,07 | 3,71 | ||

| 6,3 | 1,67 | 2,31 | 4,13 | ||

| 7,1 | 1,86 | 2,58 | 4,61 | ||

| 8,0 | 2,07 | 2,87 | 5,14 | ||

| 10,0 | 2,52 | 3,50 | 6,27 | ||

| 100 | 108,0 | R=100 | R=142,5 | R=252,5 | |

| b=154 | b=196 | b=306 | |||

| 3,6 | 1,46 | 2,08 | 3,68 | ||

| 4,0 | 1,61 | 2,30 | 4,07 | ||

| 4,5 | 1,81 | 2,57 | 4,56 | ||

| 5,0 | 2,00 | 2,85 | 5,04 | ||

| 5,6 | 2,22 | 3,17 | 5,61 | ||

| 6,3 | 2,48 | 3,54 | 6,27 | ||

| 7,1 | 2,78 | 3,96 | 7,01 | ||

| 8,0 | 3,10 | 4,42 | 7,83 | ||

| 10,0 | 3,40 | 3,50 | 9,59 | ||

| 114,3 | R=102 | R=152 | R=270 | ||

| b=159 | b=210 | b=327 | |||

| 3,6 | 1,62 | 2,36 | 4,17 | ||

| 4,0 | 1,80 | 2,61 | 4,62 | ||

| 4,5 | 2,01 | 2,92 | 5,17 | ||

| 5,0 | 2,23 | 3,23 | 5,72 | ||

| 5,6 | 2,48 | 3,60 | 6,37 | ||

| 6,3 | 2,77 | 4,02 | 7,12 | ||

| 7,1 | 3,10 | 4,50 | 7,96 | ||

| 8,0 | 3,46 | 5,03 | 8,90 | ||

| 10,0 | 4,24 | 6,16 | 10.9 | ||

| 125 | 133,0 | R=125 | R=181 | R=321,5 | |

| b=192 | b=247 | b=379 | |||

| 4,0 | 2,50 | 3,62 | 6,25 | ||

| 4,5 | 2,80 | 4,06 | 7,00 | ||

| 5,0 | 3,10 | 4,49 | 7,75 | ||

| 5,6 | 3,46 | 5,00 | 8,64 | ||

| 6,3 | 3,87 | 5,60 | 9,66 | ||

| 7,1 | 4,33 | 6,27 | 10,8 | ||

| 8,0 | 4,84 | 7,01 | 12,1 | ||

| 139,7 | R=127 | R=190 | R=330 | ||

| b=197 | b=260 | b=400 | |||

| 4,0 | 2,79 | 4,01 | 6,94 | ||

| 4,5 | 3,13 | 4,49 | 7,78 | ||

| 5,0 | 3,46 | 4,97 | 8,61 | ||

| 5,6 | 3,86 | 5,54 | 9,60 | ||

| 6,3 | 4,32 | 6,20 | 10,8 | ||

| 7,1 | 4,83 | 6,95 | 12,0 | ||

| 8,0 | 5,41 | 7,78 | 13,5 | ||

| 150 | 159,0 | R=150 | R=216 | R=375 | |

| b=230 | b=294 | b=454 | |||

| 4,5 | 4,04 | 5,82 | 10,1 | ||

| 5,0 | 4,48 | 6,45 | 11,2 | ||

| 5,6 | 4,99 | 7,19 | 12,5 | ||

| 6,3 | 5,59 | 8,05 | 14,0 | ||

| 7,1 | 6,27 | 9,03 | 15,7 | ||

| 8,0 | 7,02 | 10,1 | 17,6 | ||

| 8,8 | 7,68 | 11,1 | 19,2 | ||

| 10,0 | 8,66 | 12,5 | 21,7 | ||

| 14,0 | - | 18,0 | - | ||

| 150 | 168,3 | R=152 | R=229 | R=390 | |

| b=237 | b=313 | b=474 | |||

| 4,5 | 4,43 | 6,53 | 11,1 | ||

| 5,0 | 4,90 | 7,23 | 12,3 | ||

| 5,6 | 5,47 | 8,07 | 13,8 | ||

| 6,3 | 6,13 | 9,04 | 15,4 | ||

| 7,1 | 6,87 | 10,10 | 17,3 | ||

| 8,0 | 7,70 | 11,40 | 19,4 | ||

| 8,8 | 8,43 | 12,40 | 21,2 | ||

| 10,0 | 9,51 | 14,00 | 23,9 | ||

| 200 | 219,1 | R=203 | R=305 | R=510 | |

| b=313 | b=415 | b=620 | |||

| 6,3 | 10,9 | 15,8 | 26,5 | ||

| 7,1 | 12,3 | 17,8 | 29,7 | ||

| 8,0 | 13,7 | 20,0 | 33,4 | ||

| 8,8 | 15,1 | 21,9 | 36,6 | ||

| 10,0 | 17,0 | 24,7 | 41,3 | ||

| 11,0 | 18,6 | 27,0 | 45,2 | ||

| 12,5 | 21,0 | 30,5 | 51,0 | ||

| 16,0 | 26,4 | 38,4 | 66,0 | ||

| 250 | 273,0 | R=254 | R=381 | R=650 | |

| b=391 | b=518 | b=787 | |||

| 6,3 | 16,5 | 24,8 | 42,3 | ||

| 7,1 | 18,6 | 27,9 | 47,5 | ||

| 8,0 | 20,9 | 31,3 | 53,4 | ||

| 8,8 | 22,9 | 34,3 | 58,5 | ||

| 10,0 | 25,9 | 38,3 | 66,2 | ||

| 11,0 | 28,4 | 42,5 | 72,6 | ||

| 12,5 | 32,0 | 48,1 | 82 | ||

| 300 | 323,9 | R=305 | R=457 | R=775 | |

| b=467 | b=619 | b=937 | |||

| 7,1 | 26,6 | 39,8 | 67,5 | ||

| 8,0 | 29,9 | 44,7 | 75,9 | ||

| 8,8 | 32,8 | 49,1 | 83,3 | ||

| 10,0 | 37,1 | 55,6 | 94,2 | ||

| 11,0 | 40,7 | 60,9 | 103 | ||

| 12,5 | 46,0 | 68,9 | 117 | ||

| 350 | 355,6 | R=356 | R=533 | R=850 | |

| b=533 | b=711 | b=1028 | |||

| 8,0 | 38,2 | 57,5 | 91.6 | ||

| 8,8 | 42,0 | 63,1 | 101 | ||

| 10,0 | 47,5 | 71,4 | 114 | ||

| 11,0 | 52,1 | 78,3 | 125 | ||

| 12,5 | 59,0 | 88,6 | 141 | ||

| 14,2 | 66,7 | 100 | 160 | ||

| 400 | 406,4 | R=406 | R=610 | R=970 | |

| b=610 | b=813 | b=1173 | |||

| 8,0 | 50,1 | 75,3 | 120 | ||

| 8,8 | 55,1 | 82,6 | 132 | ||

| 10,0 | 62,4 | 93,6 | 149 | ||

| 11,0 | 68,5 | 103 | 163 | ||

| 12,0 | 77,5 | 116 | 185 | ||

| 14,2 | 87,7 | 131 | 209 | ||

| 450 | 457,0 | R=457 | R=686 | R=1122 | |

| b=686 | b=914 | b=1351 | |||

| 8,0 | 63,3 | 95,5 | 156 | ||

| 8,8 | 69,5 | 105 | 171 | ||

| 10,0 | 78,8 | 119 | 194 | ||

| 11,0 | 86,5 | 130 | 213 | ||

| 12,5 | 98 | 148 | 242 | ||

| 14,2 | 111 | 167 | 274 | ||

| 500 | 508,0 | R=508 | R=762 | R=1245 | |

| b=762 | b=1016 | b=1499 | |||

| 8,0 | 78,2 | 118 | 193 | ||

| 8,8 | 85,9 | 130 | 212 | ||

| 10,0 | 97,4 | 147 | 240 | ||

| 11,0 | 107 | 161 | 264 | ||

| 12,5 | 121 | 183 | 299 | ||

| 14,2 | 137 | 207 | 338 | ||

| 600 | 610,0 | R=610 | R=914 | R=1525 | |

| b=915 | b=1210 | b=1830 | |||

| 10,0 | 142 | 209 | 348 | ||

| 11,0 | 156 | 230 | 383 | ||

| 12,5 | 176 | 260 | 434 | ||

| 14,2 | 200 | 295 | 491 | ||

| 16,0 | 224 | 331 | 552 | ||

| 17,5 | 245 | 361 | 602 | ||

| 700 | 711,0 | R=711 | R=1067 | R=1778 | |

| b=1067 | b=1422 | b=2133 | |||

| 10,0 | 190 | 285 | 475 | ||

| 11,0 | 209 | 313 | 521 | ||

| 12,5 | 237 | 355 | 592 | ||

| 14,2 | 268 | 403 | 671 | ||

| 16,0 | 302 | 452 | - |

DIN 2605-1 Type 5 Elbow Packing and Shipping

DIN 2605-1 Type 5 Elbow in are Palletize with Shrink Wrap Plastic or Packed in Wooden Box.

Both ends of each crate will indicate the order no., heat no., dimensions, weight and bundles or as requested. We can also offer customized packaging for DIN 2605 Elbow as per customer's requirement.

Export packaging is geared towards the protection, handling and transport of DIN 2605-1 Type 5 Elbow by air or sea freight and, as such, shares many characteristics with export and transport packaging. Utmost care must also be taken to make overseas packaging suitable for long periods of storage. It is important for overseas packaging to be designed with ease of handling in mind, so as to ensure DIN 2605 Elbow is treated with the utmost care at all times.

DIN 2605-1 Type 5 Elbow Application

- Marine fixtures, pumps, valves and piping systems for sea water applications

- Chemical plant equipment

- Aerospace applications

- Musical instruments

- Heat exchangers

- High pressure applications

- Offshore applications

- Onshore applications

- Welded pressure vessels for the storage of cryogens

DIN 2605-1 Type 5 Elbow Export Countries

We export DIN 2605-1 Type 5 Elbow to Saudi Arabia, Iran, Iraq, United Arab Emirates, Qatar, Bahrain, Oman, Kuwait, Turkey, Egypt, Yemen, Syria, israel, Jordan, Cyprus, Singapore, Malaysia, Indonesia, Thailand, Vietnam, South Korea, Japan, Sri Lanka, Maldives, Bangladesh, Mayanmar, Taiwan, Cambodia, Argentina, Bolivia, Brazil, Chile, Venezuela, Colombia, Ecuador, Guyana, Paraguay, Uruguay, United States Of America, Canada, Mexico, Panama, Costa Rica, Puerto Rica, Trinidad And Tobago, Jamaica, Bahamas, Denmark, Russia, Norway, Germany, France, Italy, United Kingdom, Spain, Ukraine, Netherland, Belgium, Greece, Czech Republic, Portugal, Hungary, Albania, Austria, Switzerland, Slovakia, Finland, Ireland, Croatia, Slovenia, Malta, Nigeria, Algeria, Angola, South Africa, Libya, Egypt, Sudan, Equatorial Guinea, The Republic Of Congo, Gabon, europe, Africa, Asia, North America, South America, Middle East, Far East.etc

Prosaic Steel and Alloys is a well known worldwide exporter of DIN 2605-1 Type 5 Elbow, Prosaic Steel and Alloys is committed to provide each and every customer with the highest standard of customer service. We deals in DIN 2605-1 Type 5 Elbow in India & Overseas, offering a wide range of DIN 2605-1 Type 5 Elbow